Since my workshop (30'x60') burnt down, I am looking to replace it with one of the prefab steel garages, probably about 30' x 40'.

Any recommendations?

What are the good manufacturers of these?

What should I look for?

Anyone in the Southern Maine / NH area know a place that sells them? (I would like to go look at a few setup first)

Thanks!

Any recommendations?

What are the good manufacturers of these?

What should I look for?

Anyone in the Southern Maine / NH area know a place that sells them? (I would like to go look at a few setup first)

Thanks!

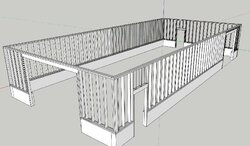

. Here's a google sketchup drawing of the layout.

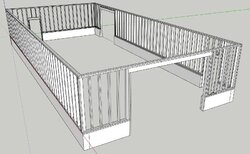

. Here's a google sketchup drawing of the layout.