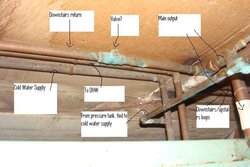

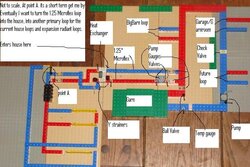

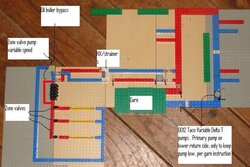

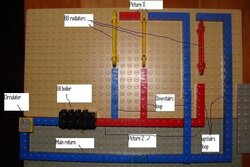

I've spent the better part of the past week trying to figure out what I have here. I can't do much more in the Garn room until I get this piping rolling. I've built my model out of legos. It's not to scale, and very simplified. I've left out the cold water fill, pressure tank, dhw in my model. It's by no means to scale, but a way to convey what I got to you hearth guys.

The pictures labeled on the model are referenced to the file name of the picture. Please advise me if you can't read the labeling on my model.

What I don't understand about my piping model is why does the downstairs loop T into a return and continues to supply the remainder of the downstairs loop and mix back in at the supply. Picture 8 is where the T is. Picture 2 shows the downstairs finishing its return at supply on boiler out side. It's confusing me bigtime!

Appreciate the help. I'm lost without it.

The pictures labeled on the model are referenced to the file name of the picture. Please advise me if you can't read the labeling on my model.

What I don't understand about my piping model is why does the downstairs loop T into a return and continues to supply the remainder of the downstairs loop and mix back in at the supply. Picture 8 is where the T is. Picture 2 shows the downstairs finishing its return at supply on boiler out side. It's confusing me bigtime!

Appreciate the help. I'm lost without it.

It will corrode everything...

It will corrode everything...