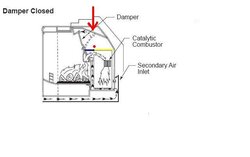

Am installing a used Vermont Castings Winter Warm -Small insert. Looking down from the chimney outlet, I can see a gap between the refractory block and the backplate and throat. As a result, I'm afraid that there will be leakage up thru that gap that will short-circuit the catalytic combustion. The combustor that same with the unit looks like it was overheated and distorted some, and I have a new one on order. That will help the combustor refractory plate fit more tightly and make less backward pressure on the whole assembly, but I think there will still be a small gap (1.2 inch). The gap is the brighter white in the photo.

One idea I have is laying a piece of gasket across the gap (above the gap, not down in it) and tacking it down to the the plate on the right with refractory gasket cement. The second photo has it laying across the gap in much the way I would do it. It doesn't interfere with the damper plate laying back across the area when open.

Any idea if this will work?

One idea I have is laying a piece of gasket across the gap (above the gap, not down in it) and tacking it down to the the plate on the right with refractory gasket cement. The second photo has it laying across the gap in much the way I would do it. It doesn't interfere with the damper plate laying back across the area when open.

Any idea if this will work?