This is my third season with this stove. Although the igniter would glow, pellets would not light. Thinking that the igniter was going bad, I replaced it and cleaned the stove, but no improvement. Pellets get hot, but still not enough to start. Any ideas?

Winslow PI40 start problems

- Thread starter boisverts

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I

imacman

Guest

Welcome to the forum, D in NH.

Have the pellets been sitting around for a long time? Has the stove been cleaned completely recently? Is the ignitor moveable?.....maybe it's too far away from the burnpot/pellets?

Have the pellets been sitting around for a long time? Has the stove been cleaned completely recently? Is the ignitor moveable?.....maybe it's too far away from the burnpot/pellets?

Wood Heat Stoves

Minister of Fire

i'd start with all the maint recommended in the technical svc manual(this will have lots more detail than the owners book...)

if you would like a copy, pm me:

model, and your email address

if you would like a copy, pm me:

model, and your email address

Winslow2010

New Member

I would give it a good cleaning, make sure the burn pot is aligned right, and try some fresh pellets. Airflow could be an issue so I would pull out the insert and clean the vent pipe. Mine had a surprising amount of ash in the clean out box that could restrict the airflow.

Our temps have warmed up here in West Virginia so my stove has shifted to part-time use. The Winslow Insert seems to prefer to run on 3 or 4. I get more ash and clinkers on the lower (1 and 2) settings. Keep us posted.

Our temps have warmed up here in West Virginia so my stove has shifted to part-time use. The Winslow Insert seems to prefer to run on 3 or 4. I get more ash and clinkers on the lower (1 and 2) settings. Keep us posted.

make sure the tube for the ignitor is real close to the burnpot, it is easy to bang into when removing and installing the burnpot, knocking the whole tube a wee too far from the pot to funnel the air through that lil hole. Also make sure the burnpot is in there really straight, off by just a few degees and the hot air just whirls around the pot, and not through the lil hole.

All good suggestions. The problem started only a couple of weeks after a thorough cleaning, including all passageways and whatever I could knock down from the flexible vent pipe. Pellets would get hot, but not ignite.

With a good flame, I presumed the igniter was failing, and replaced it. I first set the new one in the same spot, but have since pushed it in as far as possible without covering the inlet holes.

I have also been speaking with the local dealer, who has discuss my problems with Lennox. He suggested checking the combustion blower duct. I avoid removing it due to the cost of the gasket. It was clean. I push a vacuum hose into it from the vent cleanout. He also suggested pointing a hair dryer at the igniter to see if it is just a matter of air flow. This worked. Even a small oscillating fan in the access door will do it.

My house is 40 years old, so it is probably not overly tight. The stove is fed by outside air. I drilled a 2" hole through the fireplace foundation, into the ash pit. The dealer suggested piping up to the stove, but I don't see why this is necessary. It has worked fine as is for the two previous winters. And yes, I did check to see that the outside opening was clear. I also tried starting the stove with a nearby window opened an inch with no change. A couple of pellets get hot enough to turn black, but no fire.

With a good flame, I presumed the igniter was failing, and replaced it. I first set the new one in the same spot, but have since pushed it in as far as possible without covering the inlet holes.

I have also been speaking with the local dealer, who has discuss my problems with Lennox. He suggested checking the combustion blower duct. I avoid removing it due to the cost of the gasket. It was clean. I push a vacuum hose into it from the vent cleanout. He also suggested pointing a hair dryer at the igniter to see if it is just a matter of air flow. This worked. Even a small oscillating fan in the access door will do it.

My house is 40 years old, so it is probably not overly tight. The stove is fed by outside air. I drilled a 2" hole through the fireplace foundation, into the ash pit. The dealer suggested piping up to the stove, but I don't see why this is necessary. It has worked fine as is for the two previous winters. And yes, I did check to see that the outside opening was clear. I also tried starting the stove with a nearby window opened an inch with no change. A couple of pellets get hot enough to turn black, but no fire.

SmokeyTheBear

Minister of Fire

Is there a tube that the igniter is inside of on your stove?

If so if there is any ash inside that tube it will block the air flow past the igniter, the same can happen if the sealant used to seal the igniter to its mounting hole or the igniter wires get into the air supply for the tube around the igniter

If so if there is any ash inside that tube it will block the air flow past the igniter, the same can happen if the sealant used to seal the igniter to its mounting hole or the igniter wires get into the air supply for the tube around the igniter

The igniter just fits through a tight fitting hole in the back wall of a box under the burn pot. No sealer. Wires come out of the end. Intake holes are on the side. No conflict. Plus I have pushed it in closer to the burn pot by more than an inch. Last night, I even enlarged the hole that aligns with the igniter. No change.

SmokeyTheBear

Minister of Fire

Would you please post a picture of the burn pot in the stove so we can see where the end of that igniter actually is.

Wood Heat Stoves

Minister of Fire

http://woodheatstoves.com/country-pellet-stove-ignitor-whose-clamp-pips40-p-9319.html

tried to link just the image, but hearth.com doesn't like links with spaces...

just a basic ignitor with a tube welded to the outside.

tried to link just the image, but hearth.com doesn't like links with spaces...

just a basic ignitor with a tube welded to the outside.

SmokeyTheBear

Minister of Fire

Wood Heat Stoves said:http://woodheatstoves.com/country-pellet-stove-ignitor-whose-clamp-pips40-p-9319.html

tried to link just the image, but hearth.com doesn't like links with spaces...

just a basic ignitor with a tube welded to the outside.

Thanks for the picture Dave.

I really wanted to see how the OP had it installed on his stove.

SmokeyTheBear

Minister of Fire

Here is why I asked for the picture.

The igniter and its tube should be as close to the burn pot's igniter hole as possible without the igniter's end actually being past the inside edge of the burn pot.

The further back from the inside edge of the burn pot the longer it will take to get the fuel heated past its ignition temperature if at all. It becomes a trade off of getting the fuel going consistently and not having the fire in the burn pot contribute to shortening the life of the igniter.

Air flow issues also enter into the mix and the issue doesn't always have to do with the exhaust side of things, a burn pot air bypass is all that is needed.

Something as simple as a loose latch on an ash pan door or bad ash pan door gasket. It all depends upon how the stove is put together. If the stove needs 50 cfm of air flow by the igniter and the combustion fan has a startup airflow of 55 cfm it doesn't take much of a leak to make fire starting problematic. All airflow volumes in this post are made up to illustrate the process.

The igniter and its tube should be as close to the burn pot's igniter hole as possible without the igniter's end actually being past the inside edge of the burn pot.

The further back from the inside edge of the burn pot the longer it will take to get the fuel heated past its ignition temperature if at all. It becomes a trade off of getting the fuel going consistently and not having the fire in the burn pot contribute to shortening the life of the igniter.

Air flow issues also enter into the mix and the issue doesn't always have to do with the exhaust side of things, a burn pot air bypass is all that is needed.

Something as simple as a loose latch on an ash pan door or bad ash pan door gasket. It all depends upon how the stove is put together. If the stove needs 50 cfm of air flow by the igniter and the combustion fan has a startup airflow of 55 cfm it doesn't take much of a leak to make fire starting problematic. All airflow volumes in this post are made up to illustrate the process.

It has been suggested to me that some folks open up the air intake holes in the igniter to increase airflow. I tried this, at least doubling the intake area. I installed it so that it is virtually touching the burn pot. Still no start.

I also closed the door on a sheet of paper to test the tightness of the gasket, which looks fine. The paper pulled out easily at the top, but was very difficult at the bottom. This may be partly due to the bends to get around a flange at the bottom. However, the gasket has no spring in it at the top; the bottom is spongy. I made several attempts to reset the door hinge and get a better seal, but could not improve it. Could a door leak be the problem? I must repeat that this problem came on suddenly with no obvious change in operations, pellets, environment, etc.

I also closed the door on a sheet of paper to test the tightness of the gasket, which looks fine. The paper pulled out easily at the top, but was very difficult at the bottom. This may be partly due to the bends to get around a flange at the bottom. However, the gasket has no spring in it at the top; the bottom is spongy. I made several attempts to reset the door hinge and get a better seal, but could not improve it. Could a door leak be the problem? I must repeat that this problem came on suddenly with no obvious change in operations, pellets, environment, etc.

CJ-SR4ever

New Member

Do you have a cap on you chimney? It is possible that after you did your cleaning alot of the left over fly ash was blown up the chimney and may have plugged up the cap. I have seen this a few times. Do you have a reline of the pipe going to the top of the chimney? And hooking up OAK to the winslow wouldnt make any difference in the operation because that does not go direct to the combustion chamber.

SmokeyTheBear

Minister of Fire

III

III

III <<< burn pot

---- <<< Igniter tube

*** <<< Igniter element

---- <<< Igniter tube

III <<< burn pot

III

III

Does this look like your igniter placement?

III

III <<< burn pot

---- <<< Igniter tube

*** <<< Igniter element

---- <<< Igniter tube

III <<< burn pot

III

III

Does this look like your igniter placement?

Anyone with a PI40 have their stove go through the ignition sequence twice in a row. Mine is igniting just fine (lining up the burn pot over the years has become an art...) it will come up to temp and start the blower but only on low, then it will begin the ignition sequence again. Meaning, it drops a bunch of pellets in, stops for feeding for about 3-4 minutes and turns the igniter (sp?) back on even though the fire is up and running. Any thoughts here?

Also, has anyone had to replace their burnpot yet? Mine is falling apart on the edges. Bought the stove back in 2003 before Lennox purchased Country.

Another one...anyone own the diagnostic device that allows you to make changes to the board? I know I can purchase one from the Lennox supply guy in New Jersey. Ebay?

Also, has anyone had to replace their burnpot yet? Mine is falling apart on the edges. Bought the stove back in 2003 before Lennox purchased Country.

Another one...anyone own the diagnostic device that allows you to make changes to the board? I know I can purchase one from the Lennox supply guy in New Jersey. Ebay?

mlobitz said:Anyone with a PI40 have their stove go through the ignition sequence twice in a row. Mine is igniting just fine (lining up the burn pot over the years has become an art...) it will come up to temp and start the blower but only on low, then it will begin the ignition sequence again. Meaning, it drops a bunch of pellets in, stops for feeding for about 3-4 minutes and turns the igniter (sp?) back on even though the fire is up and running. Any thoughts here?

Also, has anyone had to replace their burnpot yet? Mine is falling apart on the edges. Bought the stove back in 2003 before Lennox purchased Country.

Another one...anyone own the diagnostic device that allows you to make changes to the board? I know I can purchase one from the Lennox supply guy in New Jersey. Ebay?

you could have a dirty POF (proof of fire) switch. Stove doesn't know its lit, so it tries to light again, and then "TADA" the min temp is hit. Not totally uncommon.

Have seen the burnpot fail a few times, also not totally uncommon, and no, i dont know where you can pick up that tool, but not sure what you'd do with it anyways. Whats your plan?

O.K. that makes sense. I'll check it next week when I do the big cleanout for the season. Believe or not we have had some unseasonally chilly weather in No. Cal. Tornadoes too if you can believe that...anyway...I would like the diagnostic tool to slow down the feeding interval upon ignition. It seems, no matter how clean or well lined up the burnpot is, the auger starts feeding the burnpot before a flame starts. Then it piles 'em on and then you get the lazy orange flame from dirty glass hell... I also want to adjust some of the fan times, etc...not sure if it can be done, but I did see my local tech make some of these adjustments when the stove had trouble igniting when I first bought the stove. Actually, this is my second stove. The first one was from a batch of stoves that were out of spec. Meaning the burnpot wouldn't line up consistently no matter what. Bam...new stove, second one has been O.K. so far. Knock on pellet bag...

smwilliamson

The Stove Guy

D in NH

I have the diagnostic tool. From time to time I'll offer up a free visit to Hearth members if you are close to a job I'm doing. Where do you live in NH? I'll be up there in a couple of weeks, Manchester on the 29th. Maybe I can swing in for a quick look.

Here are the problems to rule out.

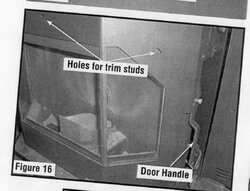

1. The igniter tube is not positioned properly. There is also an ajustment on the burn pot too. Four screws that you can loosen to move the entire burn pot back and fourth about a 1/4 inch to take up the distance from the igniter tube.

2. The igniter tube itself is NOT riding high in the fire wall through the stove. The tube of the igniter needs to fit through the hole above the square cut out in the fire wall. It is possible for the igniter tube to fall below the hole cut out and miss the intake hole on the burn pot. I knwo because I have done it on a few occasions while in a hurry.

3. Your proof of fire (low limit) switch is bad and is stuck in the closed position. you can rule this out if the igniter is in fact getting hot at start up.

4. There is a blockage of air flow somewhere in the system or the combustion motor is dirty or weak; it's enough to affect the air flow but not enough to open the vac switch sensor. Rare but still possible.

I have the diagnostic tool. From time to time I'll offer up a free visit to Hearth members if you are close to a job I'm doing. Where do you live in NH? I'll be up there in a couple of weeks, Manchester on the 29th. Maybe I can swing in for a quick look.

Here are the problems to rule out.

1. The igniter tube is not positioned properly. There is also an ajustment on the burn pot too. Four screws that you can loosen to move the entire burn pot back and fourth about a 1/4 inch to take up the distance from the igniter tube.

2. The igniter tube itself is NOT riding high in the fire wall through the stove. The tube of the igniter needs to fit through the hole above the square cut out in the fire wall. It is possible for the igniter tube to fall below the hole cut out and miss the intake hole on the burn pot. I knwo because I have done it on a few occasions while in a hurry.

3. Your proof of fire (low limit) switch is bad and is stuck in the closed position. you can rule this out if the igniter is in fact getting hot at start up.

4. There is a blockage of air flow somewhere in the system or the combustion motor is dirty or weak; it's enough to affect the air flow but not enough to open the vac switch sensor. Rare but still possible.

smwilliamson said:D in NH

Thanks for the reply and the info.

1. The igniter tube is not positioned properly. There is also an ajustment on the burn pot too. Four screws that you can loosen to move the entire burn pot back and fourth about a 1/4 inch to take up the distance from the igniter tube.

I have to turn my burnpot about 5 degrees clockwise to get it to line up. If I can move the pot say a 1/4 inch to the right that might solve that problem. I'm pretty sure the igniter is working. It pretty much always lights, just slower sometimes than other.

2. The igniter tube itself is NOT riding high in the fire wall through the stove. The tube of the igniter needs to fit through the hole above the square cut out in the fire wall. It is possible for the igniter tube to fall below the hole cut out and miss the intake hole on the burn pot. I knwo because I have done it on a few occasions while in a hurry.

3. Your proof of fire (low limit) switch is bad and is stuck in the closed position. you can rule this out if the igniter is in fact getting hot at start up.

I will check the switch. It has to have a sensor that could need cleaning.

4. There is a blockage of air flow somewhere in the system or the combustion motor is dirty or weak; it's enough to affect the air flow but not enough to open the vac switch sensor. Rare but still possible.

Here is my main problem. I think the flue pipe is in dire need of cleaning. I had another question about cleaning the flue. The top of the flue pipe is riveted in place. Should I drill out those rivets and remove the top or is there any easier way to remove the cap? I figure I'll just drill them out and refasten the top with some sheet metal screws.

had a similar problem with mine , winslow pi-40 insert, would not lite, i did a thorough cleaning,flu ports on sides, upper and lower, they were full of ash, after cleaning, lit right up, i think with the flu area's full of ash, combustion air not getting to burn pot, also u can check ignitor by plugging into an electrical socket after unwiring from stove to see if it works, i did not have to replace mine.

briansol

Minister of Fire

Old thread, but i have the same stove and have gone through a bunch of PITA little problems with it over the past few years.

Make sure it's clean. EVERYTHING. And then do it again to make sure.

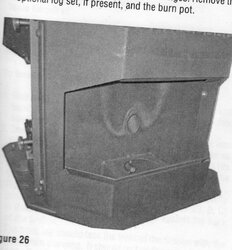

Then, check the draft adjuster (open the right door and kinda dor a reach around-- its right behind the ash pan on the inside there. Mine somehow rattled itself closed and needed to be re-opened to allow air back in the box.

Make sure it's clean. EVERYTHING. And then do it again to make sure.

Then, check the draft adjuster (open the right door and kinda dor a reach around-- its right behind the ash pan on the inside there. Mine somehow rattled itself closed and needed to be re-opened to allow air back in the box.

vmcalexander

New Member

Since this thread is related to the P140, I'm hoping someone can help with this question. Last fall after running my insert for 1.5 yrs., I called the installer to have someone come to do a yearly maintenance/cleaning before last winter. They came and since I'd already done a normal removal of ashes, all they did was open the ride side access and vacuum out around what I guess is the combustion blower which I'd been doing every couple of months anyway. They charged me $90 and said that's what was included in a yearly maintenance routine. I'm limited in who I can find to do this work in this area and I know I should just learn to do the stuff myself but.....

Last winter, I started to have a buildup of ash on the little ledge above window and so the window became blackened much more quickly than in the past. For sure I figure I need a real "check up" with the flu pipe, etc but I need to know what I need to specify that needs to be done so I can then get a cost estimate and make sure I'm actually getting the stove checked out. When I call for a furnace system/AC check-up, they have a list of what is done. I need to be able to make sure I know what should be done. For example among other items, the manual says the proof of fire switch should be cleaned after 100 bags of fuel is burned so I would expect this to be on a yearly maintenance list, right?

So what should a yearly check up include and generally what should be the cost?

Last winter, I started to have a buildup of ash on the little ledge above window and so the window became blackened much more quickly than in the past. For sure I figure I need a real "check up" with the flu pipe, etc but I need to know what I need to specify that needs to be done so I can then get a cost estimate and make sure I'm actually getting the stove checked out. When I call for a furnace system/AC check-up, they have a list of what is done. I need to be able to make sure I know what should be done. For example among other items, the manual says the proof of fire switch should be cleaned after 100 bags of fuel is burned so I would expect this to be on a yearly maintenance list, right?

So what should a yearly check up include and generally what should be the cost?

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 295

- Replies

- 2

- Views

- 602

- Replies

- 0

- Views

- 233

- Replies

- 15

- Views

- 1K