TL;DR

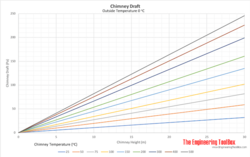

Getting additional draft is easy: add more pipe. Reducing draft is wrought with compromise and with current restrictions is

technically impossible. The overdraft problem is virtually universal; even with a flat roof, any two story house will have a stack taller then mfg recommendations. This is illogical, poses eminent danger and should be rectified with extreme prudence

As we are typing at each other with no verbal/facial cues, I will assume you are not being snarky and just scanning / reading quickly... So I will elaborate.

The calculations DO mean something, maybe not in your world but in theory and in practice for other professions. A heat reclaimer by definition reduces flue temp. I'm proposing a heat reclaimer with enhanced controls that does not allow

excessive cooling.

A device like this is not currently made in the US as far as I know but could easily be diy... I'm thinking it would include a bypass damper and variable control fan. Once the fire was established, reclaimer bypass would be closed and flu gases would be redirected through tubes similar to boilers/current reclaimers. A continuously variable digitally controlled fan would use a thermocouple probe inserted near the chimney cap to ensure the flue exit temps do not drop below critical level. Depending on the thermal efficiency, it may be necessary to also track inlet temp or draft itself to ensure the total system draft is maintained through the entire burn cycle.

Regarding the potential pitfalls of an elevated air intake, please elaborate. I'm pretty sure I've got a firm grasp of all potential pitfalls, however I actually enjoy learning and encourage critiques so please, I'm all ears.

HA! Thats nothing! I'm happy if I get 20k miles on my brakes! Brake late, brake hard. I'm roughly 1:1 brake/tire changes right now.

So EPA emissions and fuel economy testing is at least designed to mimic real life end user conditions.... It's GREAT to hear that the big brain regulators throw that logic out of the window when trying to regulate on of MANS OLDEST TECHNOLOGIES.

How many burning hours/cords per year are used in zones <4 vs zones 4 and above? At least 3/4 of the country is in climate zone 4 or higher, which I wager is where most wood burning occurs and where wood burning most dramatically effects air quality. EPA does not test emissions of vehicles at full throttle/max RPM, they test where the car spends 99% of its life: startup, idle, part throttle acceleration and freeway cruise. If 99% of the burning is done at 32F ambient and flues have virtually no maximum height but do have a hard minimum height, what cat brained bureaucrat decided testing in the current manner was a good idea? If I put on my tin foil hat, the only explanation that makes sense is the EPA is purposefully trying to put us in an impossible situation so we stop burning wood all together.

OK.... I have a few thoughts on this.

- Commercial boiler/power generation/gas residential appliances ALL have to cope with the same variables and have controls in place to regulate them; designed and integrated based on CALCULATIONS

- if all responsibilities fall on the mfg for allowing installation configurations, there should be more guidance

- if that responsibility is shoved down to sweeps/installers, where is their training/guidelines/certifications? Why are they not held to the same standards that all other contractors are held to ie calculations, not guess and check

- if calculations are useless, how did you @BKVP arrive at thechimney height recommendations for various elevations? SWAG? Seems you are at least doing some basic air density adjustments

- draft, stack velocity, thermo dynamics are not PFM... The fundamentals are very basic, and we have this new thing called Computational Fluid Dynamics. If we can correctly model/predict/design the thermal transfer of a heat sink, the airflow around a body in motion, the way atomized fuel droplets bounce off of a piston or the thermal losses through a complex building envelop comprised of many varying materials and assemblies... we can CERTAINLY generate some common flue models and establish some standards.

If mfgs put $100 bills in manuals, I would be a very wealthy man! Speaking of manuals

- My old PI1010A manual does in fact state 0.05" WC operating on high and 0.06" as unsafe... That's a very, very tight band.

- - - - HOWEVER - - - -

- NONE of the current manuals that I checked have any draft specification (I looked at 5, I'll keep my eye on the mailbox for that $500 check

), though .'...maintain draft to manufactured specifications' is sited in combustor troubleshooting and sections 'DRAFTS' and 'CHIMNEY DRAFTS' sections are referenced but are MIA. The only exception I found was PI29 manual where the 'Combustor Troubleshooting' does at least mention 'do not exceed 0.06"WC'

), though .'...maintain draft to manufactured specifications' is sited in combustor troubleshooting and sections 'DRAFTS' and 'CHIMNEY DRAFTS' sections are referenced but are MIA. The only exception I found was PI29 manual where the 'Combustor Troubleshooting' does at least mention 'do not exceed 0.06"WC'

ff

), though .'...maintain draft to manufactured specifications' is sited in combustor troubleshooting and sections 'DRAFTS' and 'CHIMNEY DRAFTS' sections are referenced but are MIA. The only exception I found was PI29 manual where the 'Combustor Troubleshooting' does at least mention 'do not exceed 0.06"WC'

), though .'...maintain draft to manufactured specifications' is sited in combustor troubleshooting and sections 'DRAFTS' and 'CHIMNEY DRAFTS' sections are referenced but are MIA. The only exception I found was PI29 manual where the 'Combustor Troubleshooting' does at least mention 'do not exceed 0.06"WC'