We recently built a house that was designed to accommodate my wood stove (woodstock fireview). This was not installed when the house was built, i am doing it now. Like many installations, clearance and space are issues - mine included. However, after years of research and planning, i believe my setup is fine... but there may be others that disagree and i'm open to suggestions and opinions. Really, I'm looking for reassurance! Here's what i have going -

1. Corner installation. As required by Woodstock, I have 12" clearance from the corners. Hearth pad is constructed per specs from Woodstock for the Fireview..

2. I'm running class A chimney straight from the stove (woodstock approved this) through a non structural and non combustible wall comprised of 20ga metal studs, hardibacker board (not durock because it breaks down at 200 degrees and max's at 10lbs sq/ft - whereas hardibacker maxes at 15lbs sq/ft with no heat limitations) and a limestone veneer. The stove connects behind the wall (yes i have access for clean out) to the main chimney and runs inside the house through an enclosed chase in the corner with proper 2" clearance (through my bedroom) and penetrates the roof near the highest point. Based on my research, this is textbook (except stove should be centrally located).

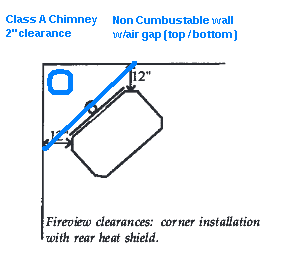

However, here's where my installation is controversial (although it shouldn't.. right?) - The non combustible wall (see terrible diagram below) is located a FEW INCHES from the rear heat shield. This is extremely close, but if a wall is non combustible it shouldn't matter, right? Also, I'll have a 1" air gap (top and bottom) for ventilation which should also act as additional heat shielding. (Hopefully?)

My biggest concern is the heat buildup in the corner and the non combustible wall. How hot will this wall get? Does it matter? Am I overlooking anything? Thoughts, opinions, reassurance ?

?

Thanks, Eric

1. Corner installation. As required by Woodstock, I have 12" clearance from the corners. Hearth pad is constructed per specs from Woodstock for the Fireview..

2. I'm running class A chimney straight from the stove (woodstock approved this) through a non structural and non combustible wall comprised of 20ga metal studs, hardibacker board (not durock because it breaks down at 200 degrees and max's at 10lbs sq/ft - whereas hardibacker maxes at 15lbs sq/ft with no heat limitations) and a limestone veneer. The stove connects behind the wall (yes i have access for clean out) to the main chimney and runs inside the house through an enclosed chase in the corner with proper 2" clearance (through my bedroom) and penetrates the roof near the highest point. Based on my research, this is textbook (except stove should be centrally located).

However, here's where my installation is controversial (although it shouldn't.. right?) - The non combustible wall (see terrible diagram below) is located a FEW INCHES from the rear heat shield. This is extremely close, but if a wall is non combustible it shouldn't matter, right? Also, I'll have a 1" air gap (top and bottom) for ventilation which should also act as additional heat shielding. (Hopefully?)

My biggest concern is the heat buildup in the corner and the non combustible wall. How hot will this wall get? Does it matter? Am I overlooking anything? Thoughts, opinions, reassurance

?

?Thanks, Eric

) Now that dropped in 30-35' of chimney, I noticed my outlet wouldn't line up... So I used a bottle jack out of my truck and lifted it! Worked perfect.

) Now that dropped in 30-35' of chimney, I noticed my outlet wouldn't line up... So I used a bottle jack out of my truck and lifted it! Worked perfect.