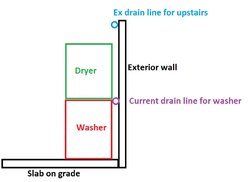

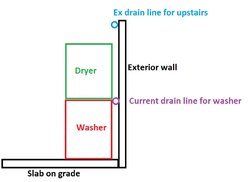

i am planning to remodel our basement shortly. we would like to move the washer dryer from its current location (shared with a bathroom) to its own room. we would also like to move an exterior door for functionality purposes. if we move the exterior door, we will be effectively eliminating a simple plumbing extension from the current washer drain location to the new washer location as the door will be cutting through where the plumbing line would be.

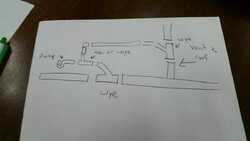

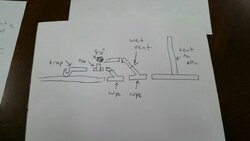

so, i'm thinking of possibly tying into a drain line coming from the upstairs kitchen.

1. is it possible to do this or is it a code violation?

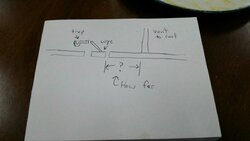

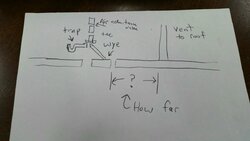

2. how high can i conceivably extend the washing machine drain line to tie into the plumbing line? i think it'll be about 7' unless i put the W/D on a platform on the floor

so, i'm thinking of possibly tying into a drain line coming from the upstairs kitchen.

1. is it possible to do this or is it a code violation?

2. how high can i conceivably extend the washing machine drain line to tie into the plumbing line? i think it'll be about 7' unless i put the W/D on a platform on the floor