I'm sure this must have been asked and answered a LOT, but my searches aren't finding what I'm looking for.

I'm trying to burn my wood efficiently, and I'd like to know if there is any agreed-upon wisdom when you should reload your stove. Once the flames stop? Once the coals sink to a certain level? Should I try to wait as long as possible, to the last moment that the coals have the ability to kindle the next load of wood?

FWIW - I have a Jotul 400 Castine. I don't use it to heat the entire house. It's in a particularly cold room, and I have fans to send some of the heat to adjacent rooms.

I'm trying to burn my wood efficiently, and I'd like to know if there is any agreed-upon wisdom when you should reload your stove. Once the flames stop? Once the coals sink to a certain level? Should I try to wait as long as possible, to the last moment that the coals have the ability to kindle the next load of wood?

FWIW - I have a Jotul 400 Castine. I don't use it to heat the entire house. It's in a particularly cold room, and I have fans to send some of the heat to adjacent rooms.

What kind of stove do you have? The Cottonwood slab wood might be pretty dry if it's been sitting in slabs for a while. I posted a couple times in another thread about how to scramble for dry wood when you are behind the eight-ball.

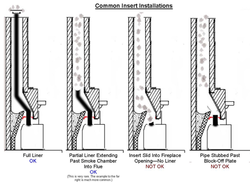

What kind of stove do you have? The Cottonwood slab wood might be pretty dry if it's been sitting in slabs for a while. I posted a couple times in another thread about how to scramble for dry wood when you are behind the eight-ball.  Really need to at least direct-connect (pipe up into the clay liner tiles, and a block-off plate,) if a full-length liner (positive connection) isn't in the cards right now...

Really need to at least direct-connect (pipe up into the clay liner tiles, and a block-off plate,) if a full-length liner (positive connection) isn't in the cards right now...

In that case, as you found out, you have to have a decent-sized coal bed to be able to burn off the moisture from a reload with wet wood. We've all been there (most of us, anyway,) and we made it through to the promised land of dry wood. Might consider getting some Bio-bricks to get you through, if you just gotta burn this season...which I think you do.

In that case, as you found out, you have to have a decent-sized coal bed to be able to burn off the moisture from a reload with wet wood. We've all been there (most of us, anyway,) and we made it through to the promised land of dry wood. Might consider getting some Bio-bricks to get you through, if you just gotta burn this season...which I think you do.