One of these fancy constant pressure pumps SOUNDS like it would be best. Not sure if you can justify the money.

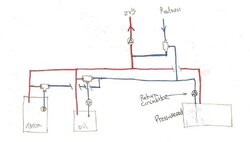

I of course will have a constant pump to supply the storage tank from the WB. That amount of heat is pretty constant. So no need there.

The variable is from the storage to my loads.

I currently have 5 zones of radiant, and one zone that's a Indirect DHW tank. Those are supplied by 4 Taco 00R pumps. As for head on them.. I guess lowest would be one that feeds basement (pump is above load, and feeds 7 loops of 300' to 350 feet of 1/2pex) max GPM of the 00Ris about 14 with zero head. So I guess that the MAX possible output of the 4 would be 56GPM. I think that number is no where near realistic.. as some of the zones go 80 feet of 3/4 out to the end of the house to a manifold, then 5 to 7 runs of the 300feet or so of 1/2 pex. All the upstairs zones are 8' or so above the level of the pumps.

My question, or my thought is that why size the pump from the top of storage to input of load circs so oversize? You'd need to plan for all 6 zones open and calling. But in reality many times it would be only DHW circ calling. Or only a zone or two.

One of these variable pumps that maintain pressure SOUNDS ideal. It could be as small as a 1/25HP.. or as big as 3/4HP.

The distance from the top of storage to load circs is going to be less than 15 feet. Since tanks are going to be vertical it's downhill 6' or so.

Thoughts? I enjoy the research and planning. Learning a lot along the way.

JP

I of course will have a constant pump to supply the storage tank from the WB. That amount of heat is pretty constant. So no need there.

The variable is from the storage to my loads.

I currently have 5 zones of radiant, and one zone that's a Indirect DHW tank. Those are supplied by 4 Taco 00R pumps. As for head on them.. I guess lowest would be one that feeds basement (pump is above load, and feeds 7 loops of 300' to 350 feet of 1/2pex) max GPM of the 00Ris about 14 with zero head. So I guess that the MAX possible output of the 4 would be 56GPM. I think that number is no where near realistic.. as some of the zones go 80 feet of 3/4 out to the end of the house to a manifold, then 5 to 7 runs of the 300feet or so of 1/2 pex. All the upstairs zones are 8' or so above the level of the pumps.

My question, or my thought is that why size the pump from the top of storage to input of load circs so oversize? You'd need to plan for all 6 zones open and calling. But in reality many times it would be only DHW circ calling. Or only a zone or two.

One of these variable pumps that maintain pressure SOUNDS ideal. It could be as small as a 1/25HP.. or as big as 3/4HP.

The distance from the top of storage to load circs is going to be less than 15 feet. Since tanks are going to be vertical it's downhill 6' or so.

Thoughts? I enjoy the research and planning. Learning a lot along the way.

JP

If nothing else.. I'll have good data to put on here to have all you guys help me tweak. It's probably all foolish anyway.. as I have confidence in Mark from AHONA. But what can I say.. I'm a professional button pusher. Gauges are my thing!

If nothing else.. I'll have good data to put on here to have all you guys help me tweak. It's probably all foolish anyway.. as I have confidence in Mark from AHONA. But what can I say.. I'm a professional button pusher. Gauges are my thing!