So ive been attempting to dig around on here to find some answers but maybe im just not good at navigating the forum so im going to do the newbie thing and make a thread.

Ive got a tarm mb solo 40 built in 2000 and in good shape i picked up used. I want to build a diy thermal storage tank. Im currently scouring for the best plans. Going pressurized isnt really an option due to where it will be. As for emitters i plan to tie this into my exisiting forced air set up that heats and cools my whole house via heat pump and elec furnace back up at the moment.

Im heating about 1400 sq foot 1 story home freshly remodeled (some still in process) with new insulation and windows all around. In southern Pennsylvania.

The boiler itself is in good shape and ive got 25 years experience operating a conventional wood boiler heating my parents house growing up and a few properties of my own over the years. The boiler will be in a 12x12 room i built off the back of my house lined with 5 inches of spray from on all sides and the ceiling. It gets toasty in there with the current forced air stove.

The storage tank i want to build will be about 25 feet a way in the basement of my house where 2 soon to be removed oil tanks sit. I plan to build with a nominal size of 4x8x4 leaving me in the ball park of 700-800 gallons depending on insulation set up. The questions i have for the storage side as this is new to me.

1- epdm liner vs sanitred. Epdm seems proven albeit maybe a 10 year window. I can live with that. Sanitred intrigues me but i cant find many ppl with experience.

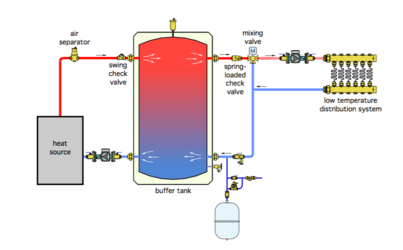

2 - has anyone used a hx coil pressurized on the boiler side to heat the storage or do is it always non pressurized with a feed and return? What are the pros and cons?

3 - on the emitter side it will be closed loop running a 12x18 air to water exhange in the plenum of my air handler and i am considering adding a cast iron radiator in my master bedroom. Is that considered i guess i would need an expansion tank on that side as that would be pressurized correct?

4 - storage tank again. I found some plans from a solar site someone on here referenced and it was plywood and 2x4s. Has anyone considered fiberglass sheets? We have a fiberglass manufacturer locally and i can source "2nds" that have esthetic blemishes. I was thinking maybe 3/8 or 1/2 inch sheets of fiberglass instead of plywood. Would i be crazy to use that and silocone the joints? Or maybe still use a liner of sorts?

5 - what size pipe should i run on either side of the storage tank?

Id appreciate any kind of feed back. Im looking to get this kit up and running in the next 4 weeks or so. Im accumulating parts as we speak.

Thanks

Ive got a tarm mb solo 40 built in 2000 and in good shape i picked up used. I want to build a diy thermal storage tank. Im currently scouring for the best plans. Going pressurized isnt really an option due to where it will be. As for emitters i plan to tie this into my exisiting forced air set up that heats and cools my whole house via heat pump and elec furnace back up at the moment.

Im heating about 1400 sq foot 1 story home freshly remodeled (some still in process) with new insulation and windows all around. In southern Pennsylvania.

The boiler itself is in good shape and ive got 25 years experience operating a conventional wood boiler heating my parents house growing up and a few properties of my own over the years. The boiler will be in a 12x12 room i built off the back of my house lined with 5 inches of spray from on all sides and the ceiling. It gets toasty in there with the current forced air stove.

The storage tank i want to build will be about 25 feet a way in the basement of my house where 2 soon to be removed oil tanks sit. I plan to build with a nominal size of 4x8x4 leaving me in the ball park of 700-800 gallons depending on insulation set up. The questions i have for the storage side as this is new to me.

1- epdm liner vs sanitred. Epdm seems proven albeit maybe a 10 year window. I can live with that. Sanitred intrigues me but i cant find many ppl with experience.

2 - has anyone used a hx coil pressurized on the boiler side to heat the storage or do is it always non pressurized with a feed and return? What are the pros and cons?

3 - on the emitter side it will be closed loop running a 12x18 air to water exhange in the plenum of my air handler and i am considering adding a cast iron radiator in my master bedroom. Is that considered i guess i would need an expansion tank on that side as that would be pressurized correct?

4 - storage tank again. I found some plans from a solar site someone on here referenced and it was plywood and 2x4s. Has anyone considered fiberglass sheets? We have a fiberglass manufacturer locally and i can source "2nds" that have esthetic blemishes. I was thinking maybe 3/8 or 1/2 inch sheets of fiberglass instead of plywood. Would i be crazy to use that and silocone the joints? Or maybe still use a liner of sorts?

5 - what size pipe should i run on either side of the storage tank?

Id appreciate any kind of feed back. Im looking to get this kit up and running in the next 4 weeks or so. Im accumulating parts as we speak.

Thanks