HarryBack said:u sure that smoke might not be coming out of that block-off plate from the hearth? Im sure you didnt just stuff the pipe up thru the damper and leave it, right? the damper is AT LEAST blocked off?

This is dealer installed. There is a cheap zero clearance fireplace behind the black sheet metal. They had to remove my original damper when the lined the 8" inch existing pipe with the four inch stainless steel liner. The 3" inch stove pipe comes from the back of the stove thru the sheet metal and into another elbow. I am not sure where the 3" to 4" pipe adapter is.

I don't see any smoke coming from behind the sheet metal with the flashlight trick. I did find a leak right at the back of the stove. The T pipe was installed with compression fit onto the stove.

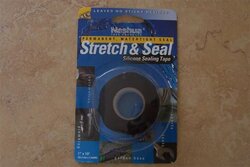

I can't find high temperature metal tape or silicon tape. Loews and Home Depot have the aluminum stuff, no temp rating. Where can I buy this tape?, brand name? 3M? I can see a half inch ash line on the pipe right behind the stove. I have high temp silicon.