DBoon

Minister of Fire

I have a small E-W stove. Square up pieces for me, mostly. Cleaved off rounds get spit into small pieces to go into the middle between square off pieces stacked in back and front.

I split into OVALS.

Seriously. How can ya split and NOT get triangles. I know ya can get some squares in the middle, but ya GOTTA have SOME triangle, unless you are starting with a SQUARE tree, right?

How to split without getting triangles? Yes, you can get some triangles but with a good sized log, you can get more rectangles or squares than triangles.

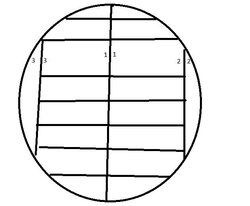

View attachment 131940

Hopefully I can explain this so it is understandable. Looking where you see the two 1's, that is splitting a round into halves. Where you see the two's and three's, this just takes a thin slab off the edge. From this point you simply turn the log so that you can then slice the remaining part into rectangles. Depending upon the size of the logs, this could be rectangles or squares.

Also, if those end up too large, they can be split once more. For example, if you had a really large log, you would first split in half. Then split like above but also split those rectangles into squares. It really is easy to do this rather you are splitting by hand or with hydraulics and you will like the results. Hope this helps.

Need I say more?

I do Hypocycloids

Why not truncated icosahedrons? Your kids could use them as toys before you burn them...........

Is this really a dilemma? Do people really argue about this?........ as well as solving the bark up vs. bark down dilemma.

Is this really a dilemma? Do people really argue about this?

I stack the wood the way that is the most stable, like playing tetris but with weight and splinters.........I don't think twice about the direction the bark faces.

I mean it is hard enough making hypocycloids, now you got me worried about which way the bark is facing......sheesh

. Red oak will usually let you have your way with it though

. Red oak will usually let you have your way with it though  .

.