Hello everyone. I've been watching this forum for a number of years but have finally decided to join and post. I'm semi-retired so I have a little time now! LOL

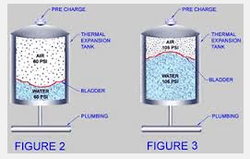

Anyhow I have a question to toss out and would appreciate any feedback. I'm currently installing a 2000 gallon pressurized storage system (LP tanks) and I'm going to use a 150 gallon LP tank for expansion. I've researched many threads on here about nitrogen filling but I don't really see anyone that has had experience with it. It would be simple enough to do but was wondering if it is even worth considering. I'm very familiar with B&G (non bladder) type expansion tanks as there are still many here in Fairbanks. Of course they only contain air. My question. Does anyone have any feedback to share on nitrogen filling expansion tank?

Anyhow I have a question to toss out and would appreciate any feedback. I'm currently installing a 2000 gallon pressurized storage system (LP tanks) and I'm going to use a 150 gallon LP tank for expansion. I've researched many threads on here about nitrogen filling but I don't really see anyone that has had experience with it. It would be simple enough to do but was wondering if it is even worth considering. I'm very familiar with B&G (non bladder) type expansion tanks as there are still many here in Fairbanks. Of course they only contain air. My question. Does anyone have any feedback to share on nitrogen filling expansion tank?