Perhaps the most common question around here is is how to best pipe multiple boilers together. And there are dozens of ways to accomplish the marriage.

Ideally you want some buffer capacity for the wood or pellet boiler. But you don't necessarily want to heat the buffer with the fossil fueled boiler.

You want to generate DHW from one or both, but not at the expense of flowing through both in series.

Also you would want to use, or upgrade heat emitters that could run down to the lowest possible temperature, that leverages your buffer capacity. A mixing device on outdoor reset would be ideal for controlling distribution temperature most efficiently, but certainly direct to higher temperature emitters would work, count on more boiler cycling, however.

Good, better best emitters hydronic baseboard, air handlers with generous coil surface, panel rads, radiant surfaces, perhaps the lowest supply requirement. Remember radiant works great in walls and ceilings, and can be retro fitted easier than a radiant slab.

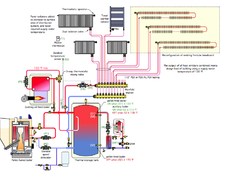

This drawing, thanks to John Siegenthaler, a hydronic designer and former Mohawk Community professor, with Appropriate Design in upstate NY, is a bit of a Euro approach. Johnnis working with NYSERDA to help installers get the best piping and help eliminate bad installations that dissuade homeowners. Not all plumbers have the experience to get the finer details correct.

Euro designs put the buffer at the end of the headers. This allows heat to get to the distribution quicker, it also lessens breaking up the stratification levels if you flowed in one side of the tank and out the other.

The fossil fueled boiler only "sees" a small portion of the buffer, for quick start up when the fire has died out. Adjust that dip tube or side port accordingly.

DHW is produced with a plate HX off the buffer tank. A small tankless, maybe even electric, would provide DHW if you chose not to fire either boiler. My system, piped with a plate HX produces plenty of DHW even with tank temperatures as low as 120F

Solar thermal could tie into this easily also.

Boiler return protection is either with a 3 way thermostatic for either or both, or with VS pumping for those that dislike mix valves

Taco released the upgrade to the BumbleBee last week, now called a Viridian model. I'm told it can now do reverse delta T, so it would be a shoe in for boiler return protection as shown here.

All other circs could be ECM for additional power savings, TRVs are excellent for non-electric proportional heat control at the emitters.

Control logic is spelled out and could be simple off the shelf aquastats, or a dual solar controller.

Air elimination is correct, expansion tank location correct, fill valve tie in, check valve locations, etc should all be correct. Boilers are shown stacked just to keep the piping easy to follow with the least amount of crossing. Boilers could be side by side, anywhere really.

Thoughts?

Ideally you want some buffer capacity for the wood or pellet boiler. But you don't necessarily want to heat the buffer with the fossil fueled boiler.

You want to generate DHW from one or both, but not at the expense of flowing through both in series.

Also you would want to use, or upgrade heat emitters that could run down to the lowest possible temperature, that leverages your buffer capacity. A mixing device on outdoor reset would be ideal for controlling distribution temperature most efficiently, but certainly direct to higher temperature emitters would work, count on more boiler cycling, however.

Good, better best emitters hydronic baseboard, air handlers with generous coil surface, panel rads, radiant surfaces, perhaps the lowest supply requirement. Remember radiant works great in walls and ceilings, and can be retro fitted easier than a radiant slab.

This drawing, thanks to John Siegenthaler, a hydronic designer and former Mohawk Community professor, with Appropriate Design in upstate NY, is a bit of a Euro approach. Johnnis working with NYSERDA to help installers get the best piping and help eliminate bad installations that dissuade homeowners. Not all plumbers have the experience to get the finer details correct.

Euro designs put the buffer at the end of the headers. This allows heat to get to the distribution quicker, it also lessens breaking up the stratification levels if you flowed in one side of the tank and out the other.

The fossil fueled boiler only "sees" a small portion of the buffer, for quick start up when the fire has died out. Adjust that dip tube or side port accordingly.

DHW is produced with a plate HX off the buffer tank. A small tankless, maybe even electric, would provide DHW if you chose not to fire either boiler. My system, piped with a plate HX produces plenty of DHW even with tank temperatures as low as 120F

Solar thermal could tie into this easily also.

Boiler return protection is either with a 3 way thermostatic for either or both, or with VS pumping for those that dislike mix valves

Taco released the upgrade to the BumbleBee last week, now called a Viridian model. I'm told it can now do reverse delta T, so it would be a shoe in for boiler return protection as shown here.

All other circs could be ECM for additional power savings, TRVs are excellent for non-electric proportional heat control at the emitters.

Control logic is spelled out and could be simple off the shelf aquastats, or a dual solar controller.

Air elimination is correct, expansion tank location correct, fill valve tie in, check valve locations, etc should all be correct. Boilers are shown stacked just to keep the piping easy to follow with the least amount of crossing. Boilers could be side by side, anywhere really.

Thoughts?