Hello everyone,

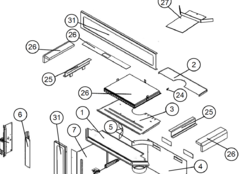

Has any one tried using '' Ceramic Exhaust Wrap '' used to wrap engine manifolds and exhaust straight pipes to make your own secondary burn gasket to seal the top of the secondary air supply tube and the bottom of the stove baffle instead of using the factory ones for the Super 27, Spectrum's and Summit stoves.

This stuff is good to 2000°F and could be a solution for making gaskets instead of purchasing and replacing a OEM gaskets every time you remove the baffle to clean and inspect the stove. It normally is 2 inch wide and can be purchased in various lengths. Just not sure how well it would work inside a firebox and resist flames.

What are your thoughts on this ?

https://sites.google.com/site/bstexhaustwrap/exhaust-wrap/ceramic-exhaust-wrap

Has any one tried using '' Ceramic Exhaust Wrap '' used to wrap engine manifolds and exhaust straight pipes to make your own secondary burn gasket to seal the top of the secondary air supply tube and the bottom of the stove baffle instead of using the factory ones for the Super 27, Spectrum's and Summit stoves.

This stuff is good to 2000°F and could be a solution for making gaskets instead of purchasing and replacing a OEM gaskets every time you remove the baffle to clean and inspect the stove. It normally is 2 inch wide and can be purchased in various lengths. Just not sure how well it would work inside a firebox and resist flames.

What are your thoughts on this ?

https://sites.google.com/site/bstexhaustwrap/exhaust-wrap/ceramic-exhaust-wrap

Last edited: