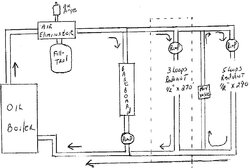

MyRanch home is currently heated with an oil boiler. This boiler also supplies my DHW. My heat is radiant in the basement. Baseboard on the main floor. I'm hooking up radiant floor on the main floor also for this season.(Except the bedrooms...they'll eventually be zoned seperately).

I am not interested in calculating heat loads or loss and my reasoning is the contractor who built my house 10 years ago did this and that's how I ended up with the oil boiler I presently use, without a want for heat or hot water.

Please don't take this statement as being cocky or arrogant. I am not. I have a lot to learn about plumbing and the only way I will grasp it is to focus on one thing at a time. Budget tells me I have to focus on tying my wood boiler into my "EXISTING SYSTEM SIMPLY".

Electric controls are no concern to me since that is what I do for a living. I also have access to people who understand plumbing and I know they will help me plumb things if need be. What I need most at this point is experience to figure how to tie a wood boiler in with my existing oil boiler most efficiently without storage.

My thoughts at this point are to run the primary pump from the wood boiler 24/7. The supply from this pump would feed the return on the oil boiler, and to complete the loop, the return to the wood boiler would be Tee'd off the Oil boiler supply after the air shovel and fill-trol.

Does that make sense?

I am not interested in calculating heat loads or loss and my reasoning is the contractor who built my house 10 years ago did this and that's how I ended up with the oil boiler I presently use, without a want for heat or hot water.

Please don't take this statement as being cocky or arrogant. I am not. I have a lot to learn about plumbing and the only way I will grasp it is to focus on one thing at a time. Budget tells me I have to focus on tying my wood boiler into my "EXISTING SYSTEM SIMPLY".

Electric controls are no concern to me since that is what I do for a living. I also have access to people who understand plumbing and I know they will help me plumb things if need be. What I need most at this point is experience to figure how to tie a wood boiler in with my existing oil boiler most efficiently without storage.

My thoughts at this point are to run the primary pump from the wood boiler 24/7. The supply from this pump would feed the return on the oil boiler, and to complete the loop, the return to the wood boiler would be Tee'd off the Oil boiler supply after the air shovel and fill-trol.

Does that make sense?