I am starting to do the detail plan to swap out my backup oil boiler on my predominately wood fired system. I have always piped boilers in general to "push" return water through the boiler with a circulator pump moving cooler return water rather than "pulling" hot supply water with circulator pump on the boiler discharge as its "harder" on the pump to deal with high temps (and in rare cases is a cavitation issue). Mty woodboiler is currently a "push through" system (I am using " " marks as these are closed loops so there really is no pushing or pulling but it may make it easier to visualize.

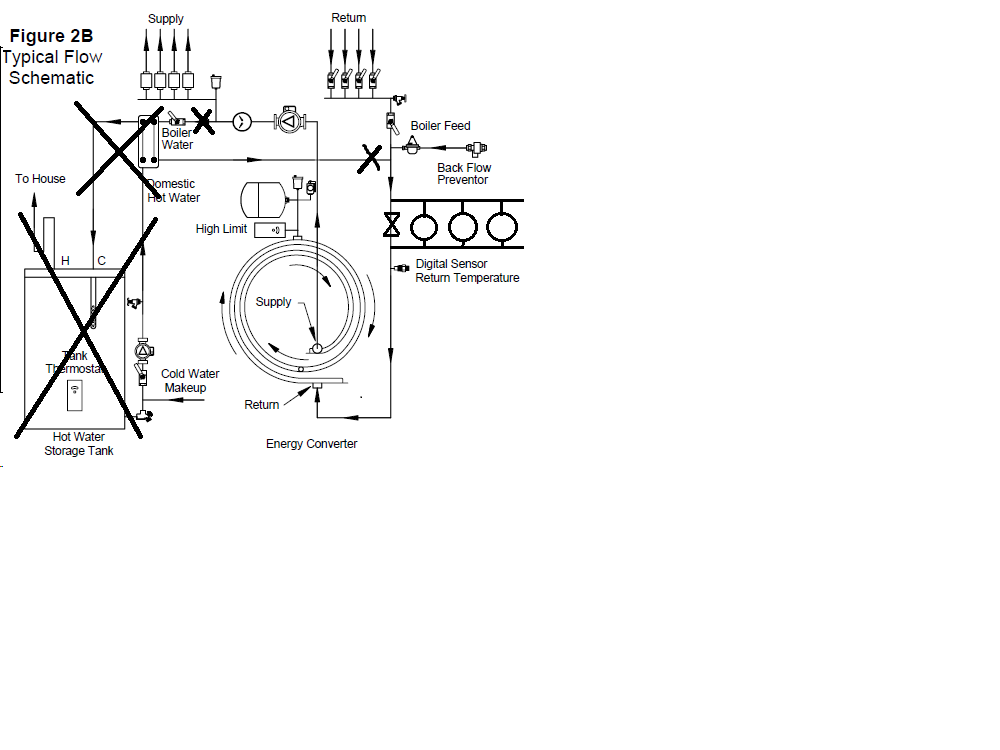

The "new" backup boiler, actually a used system 2000 cold start boiler, is currently piped as a "pull" through with four zone valves. The System 2000 is usually set up as "smart" boiler that maximizes energy efficiency by running a circulator after the thermostats have stopped calling for heat so that the boiler is normally cold when not calling for heat. It has a very low water volume compared to standard boiler and low mass which means a quick startup. It is plumbed as a "pull" through boiler. I marked up their installation sketch to get rid of domestic hot water and added three push through circulators to replace the zone valves. There are actually none return valves on each zone where the zone valves would be located.

So anyone have comments on if going to push through with this boiler (AKA energy converter in the sketch)will be an issue?

The wood boiler uses a Taco heating controller to run the zones and swapping to zone valves would be a major PITA.

So

The "new" backup boiler, actually a used system 2000 cold start boiler, is currently piped as a "pull" through with four zone valves. The System 2000 is usually set up as "smart" boiler that maximizes energy efficiency by running a circulator after the thermostats have stopped calling for heat so that the boiler is normally cold when not calling for heat. It has a very low water volume compared to standard boiler and low mass which means a quick startup. It is plumbed as a "pull" through boiler. I marked up their installation sketch to get rid of domestic hot water and added three push through circulators to replace the zone valves. There are actually none return valves on each zone where the zone valves would be located.

So anyone have comments on if going to push through with this boiler (AKA energy converter in the sketch)will be an issue?

The wood boiler uses a Taco heating controller to run the zones and swapping to zone valves would be a major PITA.

So