chris-mcpherson said:

I got the meter yesterday and am a little surprised. I tested some wood that I thought would be borderline and it's showing 10%-15%. I then tested Red Oak that was cut down less than3 months ago and split less than 1 month ago and it's showing 20%-25%.

The whole reason I got the meter was because I assumed the wood I have wasn't seasoned enough because of the tough time I'm having keeping a good fire going without the draft controls wide open. The next morning I have chunks of wood mixed in the ash... this tells me I have wet wood. Am I getting inaccurate readings because of the FSP your describing? Is there a standard that can be used to test the accuracy of my meter?

I only brought up the FSP because the meters some folks have (mine included) give a reading of up to 42% MC, but that is so far above the FSP that these readings can't be trusted. In your case, the spurious readings have nothing to do with the FSP as you are getting readings way below that point. I simply find it very hard to accept that you could cut red oak and have it burnable in 3 months, no matter when you split it or where in the country you seasoned it. Most others on this board would agree. Based on what you are telling us about the quality of your burn, I really think your wood may not be ready to burn. Therefore, there may be something wrong with your meter.

But first...

- How big are your splits on average? If you split them really thin, they may in fact already be seasoned.

- Did you re-split the wood and take a reading from the fresh faces? This is absolutely essential to do, wood dries very rapidly on the outside.

- Did you bring the wood inside to get it up to temperature? Otherwise, you need to make a temperature correction.

- Did you push the prongs into the sides (not the ends) with the prongs running in the same direction as the long grain? Failure to do this can skew your results by a couple of points.

- Did you hold the prongs in firmly, and long enough to get a steady reading?

- You may need to make a few points correction one way or the other depending on what species you are measuring. Red oak, however, should need no correction.

As far as a standard goes, if you push the prongs into your palm, you are supposed to get a reading of about 35% MC. Of course, that depends on what species you are. :cheese:

But the plot thickens...

Calibration

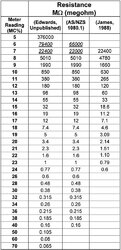

Most resistance moisture meters use Douglas-Fir (Pseudotsuga menziesii) as their default species calibration. Table 2 shows the Australian resistance values used as the Douglas-Fir standard (Edwards, 1974 and AS/NZS 1080.1: 1997). Note, there is a slight discrepancy between the figures shown for meter readings of 6 and 7 % between Edwards (1974) and AS/NZS 1080.1 (1997).

Confounding the issue of Douglas-Fir calibration, is that different world regions and different meter manufacturers can, and do, use different standard resistances for Douglas-Fir. To illustrate this point, resistance values for Douglas-Fir (Coastal) from James (1988) are included in Table 2. Skaar (1988) confirms that these are the resistance values used by most US made resistance moisture meters. Many meter manufacturers do not actually provide or specify the standard resistances they use as their Douglas-Fir calibration.

The table below contains the resistance data for Doug Fir from three different sources. As you can see, two of them concur with each other, the third is way different. According to the text quoted, the third column (James [1988]) contains the resistance figures that are used to calibrate most American made meters (i.e. Delhorst). Where was yours made? :shut:

At any rate, if you accept that yours was probably calibrated to the U.S. standard, you can go to Radio Shack and get 2 or 3 resistors that correspond to the values of interest on the tables and see if they agree with your meter. For example, a 600 KOhm resistor should give a reading of 24% MC on your meter, 2.14 MOhm should read 20%. etc. But I bet you're not likely to go to all that trouble. ;-)

I wish it could be easier. People want to just go out and purchase a cheap device that takes the doubt out of their efforts and they end up having more doubt. Or else they just blindly trust the device. That's why many here (including myself) don't think using meters is the best way to go. I bought one, found the results interesting, checked the calibration using the oven-dry method and find that it's close enough for government work. Beyond that, the tried and true method of storing your wood for a long time and testing it by burning some in your stove works best.