Hi Coley and other Fisher experts,

Thank you so much for all the information you've posted. I read this thread and related links for a few hours, and I am still unsure about a couple of things:

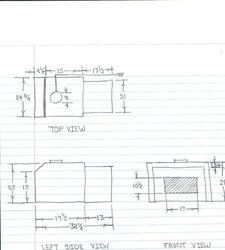

1) MODEL: the Fisher insert I have, which was already installed in the house's fire place, has an 8" flu, double doors, but it's 24 1/2" across the top plate (not 25 1/2 like Grandma Bear) and about 30" - 31" long (hard to measure very exactly without removing the insert - the inside dimension from back wall above the bricks to front wall inside door is 28 5/8", and the top plate sticks out 2" past that. If the back wall is 1/4" thick, that would make the stove's top plate just under 31" long). Counting in bricks, it has 4 lined in the back, and 6 lining each side wall. It does not have a fire grid, glass front, or more a modern door that opens in two stages to avoid back draft. Also, the top plate is flat all the way from front to back. The doors have the classic design with the brass-colored pine trees and tilted Fisher name, and also a frame with same color, about 1" wide. ( I don't know that it's actual brass, the color looks too yellow to be steel, and too silvery to be brass, and I suppose brass melts too easily for an insert door). Also, the doors are not square, they are arched at the top. The whole thing is in top condition, and has probably seen little use. Would you guys know what exact model this is?!? And where the manual is?

2) OPTIMIZING EFFICIENCY. Denver has pretty sunny winters where solar heat makes a lot of sense. I work in solar thermal, and I'm about to retrofit our typical combination solar thermal system in the house. This will take care of 70% of the total hot water and space heating for the house. However, for the remaining 30%, we do get bad winter storms where the solar is useless, and I have cords of wood in the yard (some cut, some on the trees, some hard, some soft). I want to use this stove as a backup. I do have a baseboard heating system as a secondary backup, but the boiler is probably less efficient than the insert, and is half dead anyhow! It sounds like this stove can work pretty good, up to 65% - 70% efficiency if done right. Also, efficiency is meaningful because Denver has a very real smog problem. I grew up with open-fire chimneys and don't have any know-how with wood stoves. I did find one helpful post saying to get the thing cranking to 550 with 3 full turns on both dampers, then close 2 turns , and when it gets hot 500F again, close it to 1/4 or 1/2 turn to run a long time at 350-450F. Is this the most efficient way to use this stove? Is there somekind of link somewhere that would carefully analyse how these insert run most efficient and give "insert for dummies" how-to instructions? To maximize efficiency, how much wood do you load in the insert, and how open should the dampers be?

We love this insert. It seems Fisher did to wood burning what Job's first Apples did to the IBM DOS logic: from 5% to 65% perfect over night!