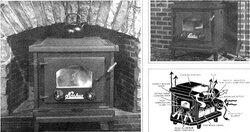

I found an early 1980's Nashua NFP-1 at a garage sale for $50.

After doing some research and seeing how well built this stove was I decided it was worthy of a second life.

The stove had been sitting in a barn for years, the owner had planned on hooking it up in the barn but never got around to it.

The restoration included:

- sandblasting off the old paint, treating the rust and repainting the stove with several coats of Rustoleum Premium High Temp paint

- scraped the lower and upper baffle surfaces

- replaced all the fire brick

- replaced the original mica glass with new Robax glass

- rebuilt and painted the blower unit

The first test burn was done outside and I was very impresses with the results...this stove can really put out the heat and burns very efficiently for a pre-EPA stove. I've owned a Waterford Trinity (EPA), ArrowWood 1500 by Heatilator, and several older stoves but this one outperforms them all.

I've now started my second heating season with this stove and have added an Air-wash system which has reduced the smoke on the glass and improved the secondary burn near the fire side of the baffel. (This stove has long slanted baffle which really improves efficiency and the 5/16" thickness creates quite a heat sink for the air chamber it surrounds that the blower circulates air through). I get long burn times (overnight) and it produced enough heat to keep a 2,000 sq. ft ranch warm through our long northern Indiana winter.

This is a great stove that's recieved a new life.

After doing some research and seeing how well built this stove was I decided it was worthy of a second life.

The stove had been sitting in a barn for years, the owner had planned on hooking it up in the barn but never got around to it.

The restoration included:

- sandblasting off the old paint, treating the rust and repainting the stove with several coats of Rustoleum Premium High Temp paint

- scraped the lower and upper baffle surfaces

- replaced all the fire brick

- replaced the original mica glass with new Robax glass

- rebuilt and painted the blower unit

The first test burn was done outside and I was very impresses with the results...this stove can really put out the heat and burns very efficiently for a pre-EPA stove. I've owned a Waterford Trinity (EPA), ArrowWood 1500 by Heatilator, and several older stoves but this one outperforms them all.

I've now started my second heating season with this stove and have added an Air-wash system which has reduced the smoke on the glass and improved the secondary burn near the fire side of the baffel. (This stove has long slanted baffle which really improves efficiency and the 5/16" thickness creates quite a heat sink for the air chamber it surrounds that the blower circulates air through). I get long burn times (overnight) and it produced enough heat to keep a 2,000 sq. ft ranch warm through our long northern Indiana winter.

This is a great stove that's recieved a new life.