huffdawg said:

Hello all, I purchased a 150 gal. lpg tank im filling it with water and 1/2 gallon of bleach right now . Is a half gal. of bleach enough and how long should I soak it for.

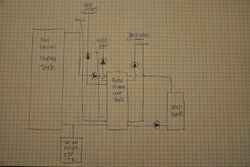

I will be using this tank as a primary loop / buffer tank . I will plumb in house loop which will supply dhw ,infloor and base board. shop infloor heating and dhw . And also a supply and return to storage .

Are there others on here that have plumbed this way and if so ,can you give tell me what i need besides supplies and returns from the heat loads and storage .

Dale

Here's mine:

https://www.hearth.com/econtent/index.php/forums/viewthread/60497/#689728

Forged weldable half-couplings (less expensive that weld-o-lets and perfectly suitable in this application):

1.25" inlet/outlet top/bottom from/to storage.

1.25" inlet/outlet top/bottom from/to oil boiler.

1.25" outlet near middle for heating load supply.

1.25" inlet bottom for heating load return.

0.75" temperature wells: apex of top, a couple inches above middle outlet port, and a couple inches above bottom ports.

0.5" drain apex of bottom.

In my case the 1.25" ports are over-sized, but I had a lot of donated 1.25" pipe to work with so that's what I went with.

In my case there are tankless coils for DHW and hot tub, so that's why heating load draws from middle so that DHW and hot tub get first shot at the hottest water, and the lower half of the tank can recirculate and draw down cooler without affecting hot zone in top of tank. But even without the integrated coils, preserving a separate zone for DHW would likely be a good idea.

One mistake I made was failing to anticipate the need for two temperature sensors in one well and had to replace one well with a larger diameter one (the well, not the 0.75" fitting).

I contoured the half-couplings with a hand grinder for weldable fit, cleaned and marked the attachment points, and took it to a fabricator. Cut the holes with a hole-saw after the couplings were in place, this worked well.

Orientation of the fittings was determined by where the tank was going and where the pipes were coming from.

--ewd