This thread is to document my progress, and so that there is some small amount of representation of this rare gem.

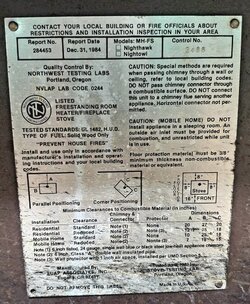

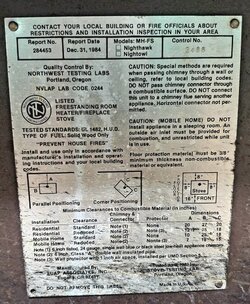

It was manufactured by Luap Associates Inc and I have no idea of the model. My decal shows two differant model choices (Nighthawk & Night owl) but neither box is checked to indicate which.

It was bought new approximately 1986 by my parents for their new double wide mobile home.

There is almost no info online about the manufacturer, and absolutely nothing about my model; not even a single picture!

What I do know is that they went out of bussiness in May of 1989, most likely due to changes in the EPA regulations. They were based out of Eugene Oregon at the following address - 2720 ROOSEVELT BLVD, EUGENE, OR, 97402

Here is a picture of it and the factory decals.

It was manufactured by Luap Associates Inc and I have no idea of the model. My decal shows two differant model choices (Nighthawk & Night owl) but neither box is checked to indicate which.

It was bought new approximately 1986 by my parents for their new double wide mobile home.

There is almost no info online about the manufacturer, and absolutely nothing about my model; not even a single picture!

What I do know is that they went out of bussiness in May of 1989, most likely due to changes in the EPA regulations. They were based out of Eugene Oregon at the following address - 2720 ROOSEVELT BLVD, EUGENE, OR, 97402

Here is a picture of it and the factory decals.

Last edited by a moderator: