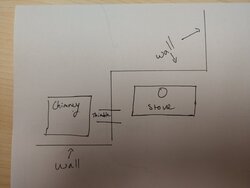

I just started roughing in my stove pipe, and realized that my Selkirk 90s won't spin. Looked around on here a little bit and it looks like others have had the same problem. Am I correct that a Selkirk 90 degree double wall won't spin to let you adjust the angle?

If so, does anyone know if the Duravent double wall will let you spin the 90s?

If so, does anyone know if the Duravent double wall will let you spin the 90s?