Hello all. I've been doing an incredible amount of research on this issue and the closest thread I can find that relates to my house is this: https://www.hearth.com/talk/threads/carbon-monoxide.172462/#post-2312430

To provide some backstory, we purchased this home in the Spring and the sellers left a stove from the 1920's. We exchanged it through a buyback program and got a Pacific Energy Super Classic 27. It is a ranch style house with a partially finished basement where the stove is installed. It was originally installed in our basement like this with doublewall pipes:

When the stove is cold, there is a good amount of cold air rushing down into it, so it makes lighting a fire pretty difficult. We usually use a torch to heat up the flue so we don't smoke out the basement. Once it gets going it drafts fine but if we don't run the fire 24/7 as it dies down and the flue gets cold, it'll reverse the draft and spill CO into the basement upwards of 50-75ppm. It's not backdrafting any smoke, just CO from uncombusted coals. The house is pretty tight so I installed an outside air kit in hopes that it was a negative pressure issue.

The fire does feel like it's running better with the OAK so I loaded it up for an overnight burn, got the stove top temp to 650 and closed down the damper to ~5% at 10pm. I woke up at 4:30am and my CO detector was showing 25ppm and when I opened the stove it jumped to 60 while I was raking the coals. I think the problem was only getting worse and if I had gotten up later it would have been much higher. There is also a radon mitigation system relatively far away in the basement. The house has 2 bathroom fans and a range fan, but they aren't being run at night, only after reloading the fire in the morning. The attic access is in the garage which is sealed off from the house, no other roof openings.

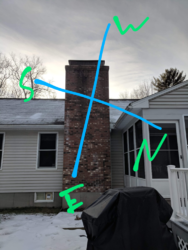

I'm starting to think the issue might be with the chimney or the basement just isn't designed for a woodstove, which would be sad. Here is what the chimney looks like:

Any input would be great!

To provide some backstory, we purchased this home in the Spring and the sellers left a stove from the 1920's. We exchanged it through a buyback program and got a Pacific Energy Super Classic 27. It is a ranch style house with a partially finished basement where the stove is installed. It was originally installed in our basement like this with doublewall pipes:

When the stove is cold, there is a good amount of cold air rushing down into it, so it makes lighting a fire pretty difficult. We usually use a torch to heat up the flue so we don't smoke out the basement. Once it gets going it drafts fine but if we don't run the fire 24/7 as it dies down and the flue gets cold, it'll reverse the draft and spill CO into the basement upwards of 50-75ppm. It's not backdrafting any smoke, just CO from uncombusted coals. The house is pretty tight so I installed an outside air kit in hopes that it was a negative pressure issue.

The fire does feel like it's running better with the OAK so I loaded it up for an overnight burn, got the stove top temp to 650 and closed down the damper to ~5% at 10pm. I woke up at 4:30am and my CO detector was showing 25ppm and when I opened the stove it jumped to 60 while I was raking the coals. I think the problem was only getting worse and if I had gotten up later it would have been much higher. There is also a radon mitigation system relatively far away in the basement. The house has 2 bathroom fans and a range fan, but they aren't being run at night, only after reloading the fire in the morning. The attic access is in the garage which is sealed off from the house, no other roof openings.

I'm starting to think the issue might be with the chimney or the basement just isn't designed for a woodstove, which would be sad. Here is what the chimney looks like:

Any input would be great!

Last edited by a moderator:

There are a few things you can do but it may only help when in the burning season.

There are a few things you can do but it may only help when in the burning season.