Good afternoon,

This is my first posting to this site. Thank you in advance. I had a Blaze King Ashford 30 installed in March of 2022. We did not run it much that season and pretty much only burned pine and almond. In the fall of 2022, when we started using it more, we started getting a very caustic, acrid, chemical, paint smell. The smell is hard to describe, but it does resemble the burn off smell we had for a while after the new stove was installed. We could never figure out where the smell was coming from nor what would cause it to happen. There is never any smoke when the smell happens. On occasion, the smoke alarm goes off, but not often. The smell has happened within five minutes of ignition, while the door is still open to allow air flow, to several hours after the fire has been going and has a nice bed of coals.

This season, starting in October, the smell has been happening more frequently; anywhere from every couple days up to twelve days. I have cleaned the piping, which is a straight run, approximately 16 feet total, several times this season to ensure the smell was not being caused by creosote buildup. I began noticing sometimes prior to the smell coming, the fire would begin to act differently and/or after adding another log to the fire and upon closing the door, with the damper still open, the flame would basically snuff itself out. I had the wood stove store that installed the stove come out and inspect the stove, catalyst and piping on the roof for any issues. They couldn't find any. At the direction of the store owner, I did the dollar bill test around the door and did find a gap by the door handle. It is getting fixed/adjusted soon.

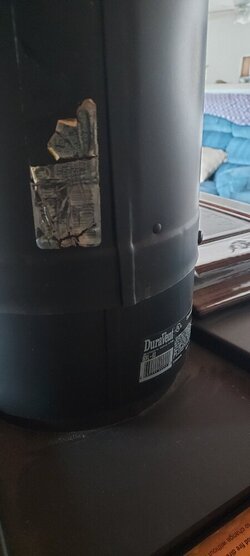

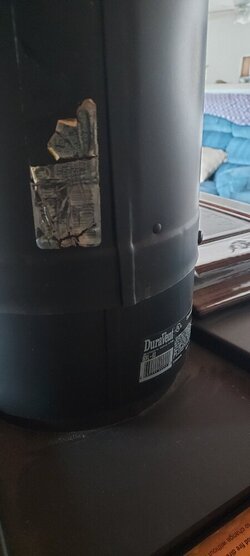

On Christmas eve morning, the smell came back about five minutes after I lit the fire. I let it burn out, cleaned out the ash, went on the roof and cleaned the pipe. Later that evening, I lit another fire, and again, within about five-ten minutes, the smell came back. My wife thought we were having a flue fire, so I ran outside and saw an odd orange glow slowly coming from the inside of the pipe. It was not an active flame, like a flue fire, and once the glow got to the top of the pipe/chimney cap, the fireball died out. I grabbed the hose and started spraying the roof to be safe and when some water hit the pipe, it sizzled as if it had been going for hours. Again, it had only been lit for about ten minutes. The outside piping is insulated double wall. Inside is non-insulated double wall black Duravent. Upon further inspection of the inside piping today, I noticed the Duravent stickers looks charred and are pealing/flaking off. When the woodstove company was out here, they said there was nothing touching the transition box and everything "looked good." I am starting to think this issue has something to do with the piping, but I am out of ideas at this point.

We are only burning well-seasoned wood that has never been sprayed or treated. All wood is tested with a moisture meter and is only used if it reads below 18%. Lately, I have only burned well-seasoned Doug Fir. We only use non-shiny newspaper to start the fire.

There is no rhyme or reason that we can find as to when the smell comes. We are extremely disheartened and aggravated.

I appreciate this site and all the help thus far. Thank you and Happy New Year!

This is my first posting to this site. Thank you in advance. I had a Blaze King Ashford 30 installed in March of 2022. We did not run it much that season and pretty much only burned pine and almond. In the fall of 2022, when we started using it more, we started getting a very caustic, acrid, chemical, paint smell. The smell is hard to describe, but it does resemble the burn off smell we had for a while after the new stove was installed. We could never figure out where the smell was coming from nor what would cause it to happen. There is never any smoke when the smell happens. On occasion, the smoke alarm goes off, but not often. The smell has happened within five minutes of ignition, while the door is still open to allow air flow, to several hours after the fire has been going and has a nice bed of coals.

This season, starting in October, the smell has been happening more frequently; anywhere from every couple days up to twelve days. I have cleaned the piping, which is a straight run, approximately 16 feet total, several times this season to ensure the smell was not being caused by creosote buildup. I began noticing sometimes prior to the smell coming, the fire would begin to act differently and/or after adding another log to the fire and upon closing the door, with the damper still open, the flame would basically snuff itself out. I had the wood stove store that installed the stove come out and inspect the stove, catalyst and piping on the roof for any issues. They couldn't find any. At the direction of the store owner, I did the dollar bill test around the door and did find a gap by the door handle. It is getting fixed/adjusted soon.

On Christmas eve morning, the smell came back about five minutes after I lit the fire. I let it burn out, cleaned out the ash, went on the roof and cleaned the pipe. Later that evening, I lit another fire, and again, within about five-ten minutes, the smell came back. My wife thought we were having a flue fire, so I ran outside and saw an odd orange glow slowly coming from the inside of the pipe. It was not an active flame, like a flue fire, and once the glow got to the top of the pipe/chimney cap, the fireball died out. I grabbed the hose and started spraying the roof to be safe and when some water hit the pipe, it sizzled as if it had been going for hours. Again, it had only been lit for about ten minutes. The outside piping is insulated double wall. Inside is non-insulated double wall black Duravent. Upon further inspection of the inside piping today, I noticed the Duravent stickers looks charred and are pealing/flaking off. When the woodstove company was out here, they said there was nothing touching the transition box and everything "looked good." I am starting to think this issue has something to do with the piping, but I am out of ideas at this point.

We are only burning well-seasoned wood that has never been sprayed or treated. All wood is tested with a moisture meter and is only used if it reads below 18%. Lately, I have only burned well-seasoned Doug Fir. We only use non-shiny newspaper to start the fire.

There is no rhyme or reason that we can find as to when the smell comes. We are extremely disheartened and aggravated.

I appreciate this site and all the help thus far. Thank you and Happy New Year!