I'm new to stoving but getting along pretty well thanks to experienced friends and Hearth.com. Our new Jotul Castine has about 12 burns through it now. I've kept a close eye on the temperatures and have gotten skilled with a quick heatup to about 550 degF (top dead center of stove), then tapering off right at 600 degF.

Last night we burned for about 5 hours between 500 & 600 degF. By bedtime, the stove had a great glowing coal bed that I had allowed it to burn down to, with a temp below 400 degF. Left the air fully on and went to bed.

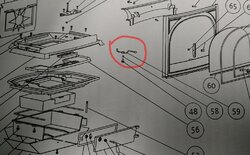

This morning I checked the stove and there was just a hint of heat left. For some reason, can't recall, I touched the air control rod to move it from 100% open to 0% open. And that's when the outermost part of the rod simply fell onto the ash lip. Holy smokes!

Examination shows the weld between the outermost part of the rod and the central pivot point "ring" failed. All I can figure is that either the rod's metal was bad or the weld was inferior. I certainly haven't overfired the stove.

Called my local dealer and got a warranty claim going. However if they say it will take 6 weeks, I will just order the part myself for $45 or so. Gotta have the fire for Christmas.

In the process of examining this failure, I've learned how the air control rod manipulates the air port in the doghouse, which I removed then reinstalled. Boy, the EUR doghouse sure is different than the USA version, anyone know more about that? Also, there is a long, third bolt in the doghouse that doesn't mate with a corresponding hole, and seems to act as a travel stop for the air port slider. Any ideas on that function?

I'll try to post some pics here.

The spooky part was imagining ramping up the stove to 500+ degrees, then having the air rod fail. Not good.

With the ash lip removed, I can see how I could still move the air control with a short piece of bent wire, in case the inside part of the rod's weld fails as well. I hate to stop burning because of this part, but since I have the bottom heatshield, I couldn't easily access the air intake if the stove tried to run away.

Last night we burned for about 5 hours between 500 & 600 degF. By bedtime, the stove had a great glowing coal bed that I had allowed it to burn down to, with a temp below 400 degF. Left the air fully on and went to bed.

This morning I checked the stove and there was just a hint of heat left. For some reason, can't recall, I touched the air control rod to move it from 100% open to 0% open. And that's when the outermost part of the rod simply fell onto the ash lip. Holy smokes!

Examination shows the weld between the outermost part of the rod and the central pivot point "ring" failed. All I can figure is that either the rod's metal was bad or the weld was inferior. I certainly haven't overfired the stove.

Called my local dealer and got a warranty claim going. However if they say it will take 6 weeks, I will just order the part myself for $45 or so. Gotta have the fire for Christmas.

In the process of examining this failure, I've learned how the air control rod manipulates the air port in the doghouse, which I removed then reinstalled. Boy, the EUR doghouse sure is different than the USA version, anyone know more about that? Also, there is a long, third bolt in the doghouse that doesn't mate with a corresponding hole, and seems to act as a travel stop for the air port slider. Any ideas on that function?

I'll try to post some pics here.

The spooky part was imagining ramping up the stove to 500+ degrees, then having the air rod fail. Not good.

With the ash lip removed, I can see how I could still move the air control with a short piece of bent wire, in case the inside part of the rod's weld fails as well. I hate to stop burning because of this part, but since I have the bottom heatshield, I couldn't easily access the air intake if the stove tried to run away.