BUILDING A FEXIBLE FOLD UP SAWBUCK

- Thread starter HDRock

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I like itI built this one without plans. I liked the idea of not having a chain. There's a handle on the far side for carrying, when it is folded. I also used treated lumber. View attachment 85741

suprz

Member

I was thinking of making one but using two pallets and just taking a few of the boards off and bolting them together in an "X" pattern

I was thinking of using pallet wood also, cuz I have a bunch of different stuff,some 3-1/2x5-1/2, 2x6s, 2x4s, 1x6s, 1x4s, and some smaller, all free pallet wood.I was thinking of making one but using two pallets and just taking a few of the boards off and bolting them together in an "X" pattern

Built a nice 6ft wood rack, from pallets, for the back deck, with a separate section for kindling.

Also been burning the pallet wood.

This deal in the vid is kinda cool to, and I have a bunch of nice straight saplings, heck U could build the whole thing from them, or a sawbuck for that matter with them.

P

Pallet Pete

Guest

Thats what I did a few years ago. Works great. Simple to make. The few boards I took off the top made support for the bottom to tie in the "X" bottom.I was thinking of making one but using two pallets and just taking a few of the boards off and bolting them together in an "X" pattern

I took two 4*6 pallets and made a saw buck that is 16" in between each rung. It has held up for 3 years so far even being untreated.

Pete

That's cool , easy , simple, plenty of support.

I gota find some more pallets, for stacking on to, I burned em up

the ones I have left are not good for stacking on

the ones I have left are not good for stacking on

P

Pallet Pete

Guest

I am the pallet master HD lol ! Look no further my friend I can get you a bunch of 49 by 73 pallets if you want.That's cool , easy , simple, plenty of support.

I gota find some more pallets, for stacking on to, I burned em upthe ones I have left are not good for stacking on

Pete

loadstarken

Burning Hunk

I am the pallet master HD lol ! Look no further my friend I can get you a bunch of 49 by 73 pallets if you want.

Pete

Pete, how much longer will you be able to get those pallets?

I am the pallet master HD lol ! Look no further my friend I can get you a bunch of 49 by 73 pallets if you want.

Pete

Great, I will come get some , Sat, Sun, Mon, ???

Boy ! I had a good pile of nails in the stove, I had to clean out

HD, please let me know when you are heading to Pete's. I'd like to meet you if possible.

Sounds good, I will , and I can pick your brain

I wish I knew half, what U do about this stuff

I wish I knew half, what U do about this stuff

P

Pallet Pete

Guest

Check your pm's HD.Sounds good, I will , and I can pick your brainI wish I knew half, what U do about this stuff

turbocruiser

Feeling the Heat

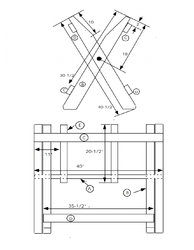

This is not my plan but ,I thought it was cool , and would be easy to build.

Wouldn't the top two crossbars get in the way too much there with that design? I built one but it isn't foldable so I think the next one will be a bit more like Dan's (I really like that design there Dan!). Maybe I'm not looking at it accurately but it looks like this plan will prove really frustrating.

I think the idea is to cut what is sticking out the end ,but ya know ! plans are good for a start, I almost always modify it, if I use a plan for somethingWouldn't the top two crossbars get in the way too much there with that design? I built one but it isn't foldable so I think the next one will be a bit more like Dan's (I really like that design there Dan!). Maybe I'm not looking at it accurately but it looks like this plan will prove really frustrating.

turbocruiser

Feeling the Heat

I think the idea is to cut what is sticking out the end ,but ya know ! plans are good for a start, I almost always modify it, if I use a plan for something

Well okay but the purpose to a sawbuck is also in sawing to the right length so typically one side of the sawbuck will size for E/W splits and the other one for N/W so on my sawbuck I have the "arms" on one side spaced at 18" and the other at 12". That way the holding, measuring and cutting are all simultaneously setup by the sawbuck.

I don't care for the design of the OP. First off, waddup with the horizontals on the top? You want to be able to run the saw down and they get in the way. I would move them down below the pivot. Oh, and that closet pole for the pivot... I would invariably hit it with the chain.

When I made my sawbuck, I countersunk all the screw heads so there is no metal for the saw chain to hit. The bottom horizontals I mounted to the inside so that I can stand closer to the work. The inside of the top section got a taper so as to hold more wood similar to the OP but the taper goes all the way down to where they meet in the cross. Mine doesn't fold but I did give it a wheel and handles to move it around.

Here is an old pic of it in action. My next version will be radically different.

When I made my sawbuck, I countersunk all the screw heads so there is no metal for the saw chain to hit. The bottom horizontals I mounted to the inside so that I can stand closer to the work. The inside of the top section got a taper so as to hold more wood similar to the OP but the taper goes all the way down to where they meet in the cross. Mine doesn't fold but I did give it a wheel and handles to move it around.

Here is an old pic of it in action. My next version will be radically different.

- Status

- Not open for further replies.

Similar threads

- Replies

- 17

- Views

- 403

- Replies

- 21

- Views

- 852

- Replies

- 0

- Views

- 193

- Replies

- 24

- Views

- 2K