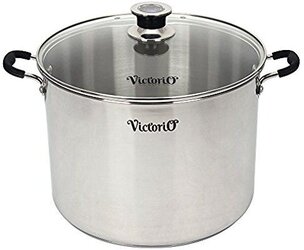

First run with my new steam canner today. I got the Victorio with the ferrous bottom that can be used on induction stove tops and can be used as both a steam canner and/or as a water bath canner. About $80 on Amazon, eligible for prime shipping.

I had seen mention of steam canning several times on youtube and ferreted out the actual science here at U of Wisconsin extension:

https://fyi.extension.wisc.edu/safefood/2020/08/18/an-update-on-safe-use-of-steam-canners/

The short version is a steam canner needs less water, so it comes up to temperature quicker, uses less energy to get up to temperature, but for high acid foods, whatever the water bath processing time is, the steam processing time is exactly the same. Doesn't matter if you are short on time or short on money, steam processing is the better choice. I don't know for sure how long it will take me to save $60 on propane, with local water bath canners around $20, but I will break even someday and I am saving a TON of time every batch in the meantime. If I was counting my propane sheckels, the steam canner is cheaper to operate every batch, so sooner or later a propane fired water bath canner user would have been ahead if they had plunked down for the steam canner to use instead.

The bad news is my altitude falls in the "first band" but I forgot to follow the yellow brick road around the dial. If you get one, think of your altitude as being in the inner, middle or outer band so you don't get confused on the other side of the dial. It is more correct to think of my processing altitude as falling at the OUTER band. Thankfully my test run was two half pints of pickled jalapeno, I can get through that in one week easily.

As a MiC stock pot it isn't bad. Doesn't hold a candle to my 20 quart stockpot stamped "Made in West Germany" in the bottom, but the Victorio is pretty OK as an $80 stock pot.

The wire basket on mine can be used for water bathing if I ever need to go there.

I have read some of the earlier product shipped with firm instructions to not use these on propane burners. I read the manual that came with mine very carefully (Aug 22) and did not find that verbiage in the current production product manual. I do have a 15k BTU/hr burner salvaged from a propane grill fabricated in to a turkey fryer burner stand and used that. The biggest burner on the electric cook stove in my kitchen was rated new at 17k BTU/ hr, so should be fine and seemed to be fine.

At full roar the 15k burner took about 30 minutes to get 3 quarts of water in the Victorio up to a full boil, more about the burner and the water, less about the pot. I shut it down, got my jalapeno diced up and my brine simmering, and then relit the burner under the steam canner. Went inside, filled my (warm from the dishwasher) jars with pepper and brine, and would have come back to the cooker in the driveway with simmering water if I was doing a bigger batch.

Overall, I give it two thumbs up after one test batch. Just think inner, middle or outer altitude band and you should do fine. I am planning to do 8-9 batches of tomato in the next few weeks and should be well on my way to breaking even on purchase price versus ongoing energy use before this season is over.

I had seen mention of steam canning several times on youtube and ferreted out the actual science here at U of Wisconsin extension:

https://fyi.extension.wisc.edu/safefood/2020/08/18/an-update-on-safe-use-of-steam-canners/

The short version is a steam canner needs less water, so it comes up to temperature quicker, uses less energy to get up to temperature, but for high acid foods, whatever the water bath processing time is, the steam processing time is exactly the same. Doesn't matter if you are short on time or short on money, steam processing is the better choice. I don't know for sure how long it will take me to save $60 on propane, with local water bath canners around $20, but I will break even someday and I am saving a TON of time every batch in the meantime. If I was counting my propane sheckels, the steam canner is cheaper to operate every batch, so sooner or later a propane fired water bath canner user would have been ahead if they had plunked down for the steam canner to use instead.

The bad news is my altitude falls in the "first band" but I forgot to follow the yellow brick road around the dial. If you get one, think of your altitude as being in the inner, middle or outer band so you don't get confused on the other side of the dial. It is more correct to think of my processing altitude as falling at the OUTER band. Thankfully my test run was two half pints of pickled jalapeno, I can get through that in one week easily.

As a MiC stock pot it isn't bad. Doesn't hold a candle to my 20 quart stockpot stamped "Made in West Germany" in the bottom, but the Victorio is pretty OK as an $80 stock pot.

The wire basket on mine can be used for water bathing if I ever need to go there.

I have read some of the earlier product shipped with firm instructions to not use these on propane burners. I read the manual that came with mine very carefully (Aug 22) and did not find that verbiage in the current production product manual. I do have a 15k BTU/hr burner salvaged from a propane grill fabricated in to a turkey fryer burner stand and used that. The biggest burner on the electric cook stove in my kitchen was rated new at 17k BTU/ hr, so should be fine and seemed to be fine.

At full roar the 15k burner took about 30 minutes to get 3 quarts of water in the Victorio up to a full boil, more about the burner and the water, less about the pot. I shut it down, got my jalapeno diced up and my brine simmering, and then relit the burner under the steam canner. Went inside, filled my (warm from the dishwasher) jars with pepper and brine, and would have come back to the cooker in the driveway with simmering water if I was doing a bigger batch.

Overall, I give it two thumbs up after one test batch. Just think inner, middle or outer altitude band and you should do fine. I am planning to do 8-9 batches of tomato in the next few weeks and should be well on my way to breaking even on purchase price versus ongoing energy use before this season is over.