Hi All,

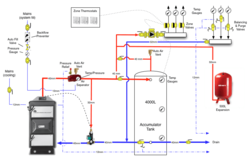

Just getting ready to start installed out new boiler. Please see attached pipe design. This is based on lot of posts I have read on the forum plus the tarm biomass manuals (PT3).

Curious to know what people think. In particular I am wondering if the pipe sizes are too big. Its a Eko 60kw boiler, heat load could max at 54kw but is expected be be around 40kw most of the time.

The tarm manual reckons 1 1/4" for but my reading of maximum BTUs though copper pipe says you need 1 1/2"....

David

Just getting ready to start installed out new boiler. Please see attached pipe design. This is based on lot of posts I have read on the forum plus the tarm biomass manuals (PT3).

Curious to know what people think. In particular I am wondering if the pipe sizes are too big. Its a Eko 60kw boiler, heat load could max at 54kw but is expected be be around 40kw most of the time.

The tarm manual reckons 1 1/4" for but my reading of maximum BTUs though copper pipe says you need 1 1/2"....

David