Anyone out there thought of a good way to reposition cordwood from a distant drying area/storage shed to your "active" wood stack. I have an indoor wood boiler that in the coldest parts of winter can burn 2 to 3 cords per month. At the present time, I have an ATV and trailer which I use but it is a lot of loading and unloading. It would be nice to stack the wood for drying on some type of inexpensive moveable base that could be repositioned using the ATV. I have a fair amount of snow so I wondering if I stacked and strapped say 1/2 a cord on a sled of sort and skidded it into position if that would be practical. Any ideas would be appreciated.

Cordwood Repositioning Systems?

- Thread starter DKerley

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Turner-n-Burner

Member

That's a tough one...

There was a thread a while back named somthing like "more wood, less handling" that talked about making various types of holders, stacking on pallets, or (my suggestion) stacking in the metal "totes" from 275gallon bulk storage tanks - think apple crates..

All of those methods assume you have a tractor with forks or the like. Even a pretty small tractor could move that with a three point rig.

But I don't have a tractor.

I use wood carts. I picked up 4 of them from harbor freight for $29 each, and I load them up when the weather is dry, and roll them under cover when the forecast calls for precipitation. 4 of them is something less than a face cord - maybe 2/3 rds? - so that's well short of your goals...

let us know what you find!

-Dan

There was a thread a while back named somthing like "more wood, less handling" that talked about making various types of holders, stacking on pallets, or (my suggestion) stacking in the metal "totes" from 275gallon bulk storage tanks - think apple crates..

All of those methods assume you have a tractor with forks or the like. Even a pretty small tractor could move that with a three point rig.

But I don't have a tractor.

I use wood carts. I picked up 4 of them from harbor freight for $29 each, and I load them up when the weather is dry, and roll them under cover when the forecast calls for precipitation. 4 of them is something less than a face cord - maybe 2/3 rds? - so that's well short of your goals...

let us know what you find!

-Dan

Highbeam

Minister of Fire

I use the tractor bucket to move bulk wood on nice days when the mud is firm every two weeks or so. I did it just yesterday to move 1/2 cord in three trips from the long drying stack into my active pile which is then loaded into a HF wood cart as turner uses. I can get 2 days worth of wood in one of those HF carts.

Keep using your ATV and trailer. Perhaps add a dump feature to the trailer or add capacity with taller sides.

Keep using your ATV and trailer. Perhaps add a dump feature to the trailer or add capacity with taller sides.

Thanks for the replies. I managed to find the link you mentioned Dan. Unfortunately, I don't have a tractor or forklift. My ATV trailer does manually dump and has stake pockets for the bigger loads. I'll keep on trying to figure this one out. I had a thought about using some corrugated steel roofing cut into sections that I could stack and strap my wood on to season then, when ready, just tow it behind the ATV into the drive thru pole shed just like a toboggan. Not too sure how much the ATV can pull with the associated friction of a sled.

kevin j

Minister of Fire

Farm show paper had a clip about a guy that stacks wood in round culvert sections. He had 4 ft long rings about 6 feet in diameter. Those were moved with pallet forks on a loader, but maybe you could do that with smaller rings and tow them sideways. Say 3 foot diamter rings, put a bar through the ring. Chains from each end of the bar to the ATV drawbar. Pulling sideways, the rounded surface would act like a runner on the snow? Because of the curve, it might sink low in the snow, but worth a try.

kcj

kcj

Thanks for the idea Kevin, I 'll be checking out the pricing of various systems and will include culvert as one of the test options.

Cheers,

Cheers,

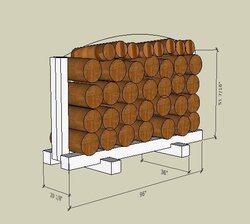

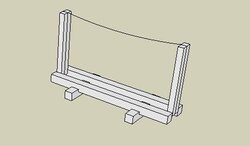

Here as a drawing of my latest idea. Basically a pallet that can hold 1/2 cord of wood. Built out of 6*6 and 4*4, a couple of carriage bolts and some cable. The plan is to rent a tractor/front loader with forks in the summer time to reposition the dry 12-15 cords of wood from drying area to the access pile. The vertical posts would fold down flat for storage when empty. Any thoughts?

Attachments

colebrookman

Minister of Fire

Very similar to one in the Farm Show newspaper. He used 2/4s on the ends extending to the ground. Then move the bottom supporst out to meet the legs and you won't need cable. But if your using a tractor why not just use pallets wrapped with used fencing to keep the wood in place as you move. You could easily take the fencing off after moving and just wrapped the next pallet. 6/6 & 4/4s are not cheap and you would need pressure treated. Just an idea that I'm going to try this fall.

Turner-n-Burner

Member

Doug,

The way you have that drawn, you have 1/3 cord, not 1/2.

Not sure what kind of ground you're going to park that on, but if it's soft, or gets soft in the spring, I think your racks may settle and tip. You might want more footprint on the ground.

you might want to add a front or back of some type - maybe lattice? - to prevent spills when you move the stack....

-Dan

The way you have that drawn, you have 1/3 cord, not 1/2.

Not sure what kind of ground you're going to park that on, but if it's soft, or gets soft in the spring, I think your racks may settle and tip. You might want more footprint on the ground.

you might want to add a front or back of some type - maybe lattice? - to prevent spills when you move the stack....

-Dan

Thanks for the replies.

Colebrookman, I have to try and figure out the way that you suggested without the cable. I do think that the cable would be a bit of a hassle so back to the drawing board.

Turn& Burn, I guess my picture doesn't show it but I buck 24", therefore, if I go 48" high its 10 cuft under 1/2 cord. If I add an additional 8" she is 64 cu ft or 1/2 cord. I am wanting to have the pile stay stacked when in the "active pile". so I though that his might be the cheapest way to go. As far a PT wood goes, I am still sitting on the fence. Need to get some prices from some local guys milling full dimension lumber first. The footprint I will have to experiment with. The ground is primary firm sand covered with a bit of grass etc. Thanks for the input.

Colebrookman, I have to try and figure out the way that you suggested without the cable. I do think that the cable would be a bit of a hassle so back to the drawing board.

Turn& Burn, I guess my picture doesn't show it but I buck 24", therefore, if I go 48" high its 10 cuft under 1/2 cord. If I add an additional 8" she is 64 cu ft or 1/2 cord. I am wanting to have the pile stay stacked when in the "active pile". so I though that his might be the cheapest way to go. As far a PT wood goes, I am still sitting on the fence. Need to get some prices from some local guys milling full dimension lumber first. The footprint I will have to experiment with. The ground is primary firm sand covered with a bit of grass etc. Thanks for the input.

granpajohn

Minister of Fire

Would PT be neccessary in the way-up-north? What would eat it?colebrookman said:...you would need pressure treated.

The reason I post this is because I had always heard it as legend, and wondering if really true.

granpajohn,

We use PT where it touches the ground. I haven't heard of the legend but who knows, maybe we are all just victims of the marketing people and we use what they sell us.

Cheers

We use PT where it touches the ground. I haven't heard of the legend but who knows, maybe we are all just victims of the marketing people and we use what they sell us.

Cheers

raybonz

Minister of Fire

DKerley said:Wood Pallet Prototype

1/2 cord (bucked 24") To be moved with a set of forks on a front end loader.

Cool lookin' racks!! What is that white stuff on the ground???

Ray

jebatty

Minister of Fire

tkirk22

New Member

I've thought through various designs ranging from a big honking pile on the ground to purpose built towable racks with wheels or skids. I settled on a cheap solution now that I have a loader.

I'm going to use oak pallets as a base with 4' tall vented sides made from scrap. I'll put pressure treated 2x4s on the bottom and use loader forks to move them to the house as needed. I would think that a similar solution would work for someone with a strong ATV. If I was dragging one, I would probably make 4x4 skids but 2x4s may be adequate. The wood probably won't dry as quick in a 4x4x4 cube but it would probably be more conducive to being dragged and/or forked without spilling the load.

BTW, Nice rack Doug. Simple and functional!

I'm going to use oak pallets as a base with 4' tall vented sides made from scrap. I'll put pressure treated 2x4s on the bottom and use loader forks to move them to the house as needed. I would think that a similar solution would work for someone with a strong ATV. If I was dragging one, I would probably make 4x4 skids but 2x4s may be adequate. The wood probably won't dry as quick in a 4x4x4 cube but it would probably be more conducive to being dragged and/or forked without spilling the load.

BTW, Nice rack Doug. Simple and functional!

colebrookman

Minister of Fire

DKerley said:Wood Pallet Prototype

1/2 cord (bucked 24") To be moved with a set of forks on a front end loader.

Looks great. should work well and save handling. A fellow in the Farm Show newspaper used a similar idea and was very happy with it. He made the end arms fold to make them easier to store when empty. I'm going to try the same for my splits and use rebar as the ends because I have some on hand. May wrap it with fencing to transport. An idea in progress. Nice job.

colebrookman said:DKerley said:Wood Pallet Prototype

1/2 cord (bucked 24") To be moved with a set of forks on a front end loader.

Looks great. should work well and save handling. A fellow in the Farm Show newspaper used a similar idea and was very happy with it. He made the end arms fold to make them easier to store when empty. I'm going to try the same for my splits and use rebar as the ends because I have some on hand. May wrap it with fencing to transport. An idea in progress. Nice job.

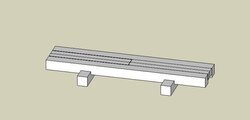

The picture doesn't show it, but the ends do fold down when empty. I used 5/8" rebar as the hinge. The whole pallet used 40 ft of 4*4 and 10-3/8 * 5" lag bolts. The cost to build it up here buying the lumber was $46.00. I am hoping to get the price down by eventually milling the lumber myself.

Attachments

Ken45

Minister of Fire

I like these ideas! It might even be worth it to me to build something like this but maybe narrower and deeper to transfer wood into at the shed and then use the 3-point on the tractor to move it into the garage for use. Unfortunately, the rollbar on the tractor won't fit under the garage door.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 3K