So I’ve been reading about this and the overwhelming Internet wisdom is never cut a truss. Never.. unless you have to. My current install plans will require me to angle back from the stove and up to avoid a truss that’s pretty much directly over the stove’s outlet.

I really don’t want to angle the pipe. I wanted a straight run for ease of cleaning, ascetics, cost, etc.

so has anyone done it? Or should I ask if anyone will admit to doing it?

In my case I have 24“ OC trusses. The span is about 22 ft. There is a wall close to we’re id cut. (the old exterior side wall is there, then a span and the next span is what I’d cut)

my initial thought is to use 3 inch angle (I have access to a bunch free) to suspend the ends from the upper using bolts. Run long angle horizontally along the truss to add support from spreading. box the opening of course and add more lumber and angle as needed to make sure it can’t spread, can’t sag, can’t twist.

Should I use an engineer? Yes, of course but they are months out in my area. So my only option is to angle the pipe or over build these trusses and cut one.

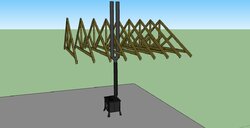

I’ll attach a pic so you can see what I’m talking about.

The stove has to be 8 inches off the wall. (Once I get the hardie and rock up that should add around 1.5 inches to that back wall) The outlet is centered at 15-3/8” off the finished wall. Ceiling box is 14x14. That truss is about 20 inches off the unfinished wall.

I really don’t want to angle the pipe. I wanted a straight run for ease of cleaning, ascetics, cost, etc.

so has anyone done it? Or should I ask if anyone will admit to doing it?

In my case I have 24“ OC trusses. The span is about 22 ft. There is a wall close to we’re id cut. (the old exterior side wall is there, then a span and the next span is what I’d cut)

my initial thought is to use 3 inch angle (I have access to a bunch free) to suspend the ends from the upper using bolts. Run long angle horizontally along the truss to add support from spreading. box the opening of course and add more lumber and angle as needed to make sure it can’t spread, can’t sag, can’t twist.

Should I use an engineer? Yes, of course but they are months out in my area. So my only option is to angle the pipe or over build these trusses and cut one.

I’ll attach a pic so you can see what I’m talking about.

The stove has to be 8 inches off the wall. (Once I get the hardie and rock up that should add around 1.5 inches to that back wall) The outlet is centered at 15-3/8” off the finished wall. Ceiling box is 14x14. That truss is about 20 inches off the unfinished wall.