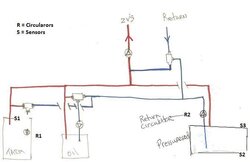

My Tarm doesn't have the pump switch hooked to anything, which seems to be the way they are installed these days. I have a Siebel controller which monitors temperatures at the Tarm, and at the top and bottom of storage. I have it set to come on when the Tarm is at least 140 and 4 degrees warmer than storage, and shut off when the differential drops to 8 degrees. After a fire, the top and bottom of the tank can be 30 degrees apart, and the pump continues to circulate and mix for a long time. For some reason, the Tarm stays warmer than the bottom of the tank for a long time, keeping the pump going for hours after the fire has gone out. Is this normal, or do I perhaps have a parameter wrong, or should I look into hooking up a defeat switch for the pump?

Defeating the pump

- Thread starter Rory

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.