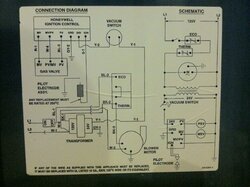

I just installed a loop on my propane water heater by tapping into the T&P valve (top) and drain valve (bottom) ports. The loop runs through a 20 plate HX nearby. My Rheem direct vent water heater has an inducer motor mounted on the top, and it plugs into an outlet on the top of the unit, which is powered by the water heater's control panel. I unplugged the inducer motor and plugged in my circ pump. The theory was that when the water heater calls for heat and sends power to the inducer motor, the circ pump will run instead. Because there is a vacuum switch in play, the propane will never fire because the inducer motor is not running. It worked great! Except it never shut off. After about an hour (130 degrees at the bottom of the tank) I unplugged the circ pump and plugged in the inducer motor. The inducer turned on for a half second and then shut off, presumably because the vacuum switch allowed power to the circuit board and the unit then realized there was no longer a call for heat. So then I took the vacuum switch out of the equation (shut off propane of course) and tried it again. It still just ran and ran.

Does anyone have a suggestion of how I could wire this so that the circ pump runs when the water heater's internal aquastat calls for heat. My only other thought would be to install another aquastat, but I can't think of an easy or good way to do that.

Does anyone have a suggestion of how I could wire this so that the circ pump runs when the water heater's internal aquastat calls for heat. My only other thought would be to install another aquastat, but I can't think of an easy or good way to do that.