Hello

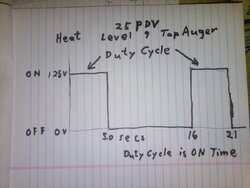

Well I did the hard reset and connected a T-Stat. What is the top auger duration or lbs/hr for each heat level from 1 - 9 ?

Main Question is:

How can I tell if the Control Board is setting the heat levels correctly?

Running the diagnostics does not step thru each heat level showing the Top Auger Duration? Maybe it should?

I did get F - 5 in the display when I did the hard reset below.

I went thru the T-Stat Test and it worked fine using a Digital Lux Non-Programmable DMH-110

http://www.englanderstoves.com/manuals/TstatTest_AutoIgnitePelletUnits.pdf

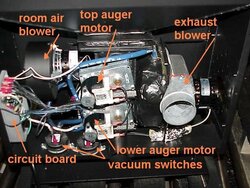

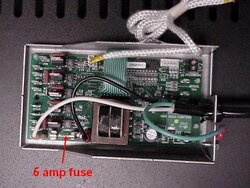

I also put the stove in Diagnostics Mode and all of those tests passed.

http://www.englanderstoves.com/help/PelletStove/diagnostic_mode04.html

Perform a hard control board reset.

1. Shut off stove, and allow to cool off completely.

2. Unplug stove, and after a few seconds plug back in....within 3-4 seconds, press all 3 bottom buttons at the same time, and let go.

3. "F-5" should appear in the display. Allow the display to go blank.

4. Re-start stove.

If this does not show F-5 readout call Englander Tech support and have them go through some other diagnostics.

Found this

https://www.hearth.com/talk/threads/baseline-fuel-burn-specs-feed-rates-for-englander-25-pdvc.11450/

"I have been looking at getting a 25-PDVC lately and talked to someone at Englander about the pellet feed rate. I was told that 1lb of pellets to makes 8000 btu of heat. On the low setting it makes 12000 btu's and uses 1.5lbs of pellets per hour. On high it makes about 40000 btu's using about 5lbs of pellets per hour. That is what I was told on the phone today."

Found this:

http://forum.iburncorn.com/viewtopic.php?p=45614&sid=3f864113986d62ed9788c87cb360a617

"I found that a good setting was 3-3-1 and 1 feed rate and 2-3 room blower this will burn about 1.3 an hr 31 lbs in 24 hrs but if you go up to 5-6 feed rate bump up your setting to 3-6-1 ,which is about 3.5 -4 lbs an

hr all was done 50/50 mix and is pretty clean burn"

St. Croix Auburn

Englander 25-PDV

Well I did the hard reset and connected a T-Stat. What is the top auger duration or lbs/hr for each heat level from 1 - 9 ?

Main Question is:

How can I tell if the Control Board is setting the heat levels correctly?

Running the diagnostics does not step thru each heat level showing the Top Auger Duration? Maybe it should?

I did get F - 5 in the display when I did the hard reset below.

I went thru the T-Stat Test and it worked fine using a Digital Lux Non-Programmable DMH-110

http://www.englanderstoves.com/manuals/TstatTest_AutoIgnitePelletUnits.pdf

I also put the stove in Diagnostics Mode and all of those tests passed.

http://www.englanderstoves.com/help/PelletStove/diagnostic_mode04.html

25-PDV Control Board Hard Reset

Perform a hard control board reset.

1. Shut off stove, and allow to cool off completely.

2. Unplug stove, and after a few seconds plug back in....within 3-4 seconds, press all 3 bottom buttons at the same time, and let go.

3. "F-5" should appear in the display. Allow the display to go blank.

4. Re-start stove.

If this does not show F-5 readout call Englander Tech support and have them go through some other diagnostics.

Found this

https://www.hearth.com/talk/threads/baseline-fuel-burn-specs-feed-rates-for-englander-25-pdvc.11450/

"I have been looking at getting a 25-PDVC lately and talked to someone at Englander about the pellet feed rate. I was told that 1lb of pellets to makes 8000 btu of heat. On the low setting it makes 12000 btu's and uses 1.5lbs of pellets per hour. On high it makes about 40000 btu's using about 5lbs of pellets per hour. That is what I was told on the phone today."

Found this:

http://forum.iburncorn.com/viewtopic.php?p=45614&sid=3f864113986d62ed9788c87cb360a617

"I found that a good setting was 3-3-1 and 1 feed rate and 2-3 room blower this will burn about 1.3 an hr 31 lbs in 24 hrs but if you go up to 5-6 feed rate bump up your setting to 3-6-1 ,which is about 3.5 -4 lbs an

hr all was done 50/50 mix and is pretty clean burn"

St. Croix Auburn

Englander 25-PDV

HOT HOT HOT

HOT HOT HOT  Mode 'B' !

Mode 'B' !