I thought it would be interesting to look at the evolution of the Fisher Stove door seals. Why? Because I've noticed that my earlier stoves had minimal welds to hold the channel iron onto the stove door opening than my newer stoves. Maybe we can sort of build or refine some timelines for when certain stoves were made.

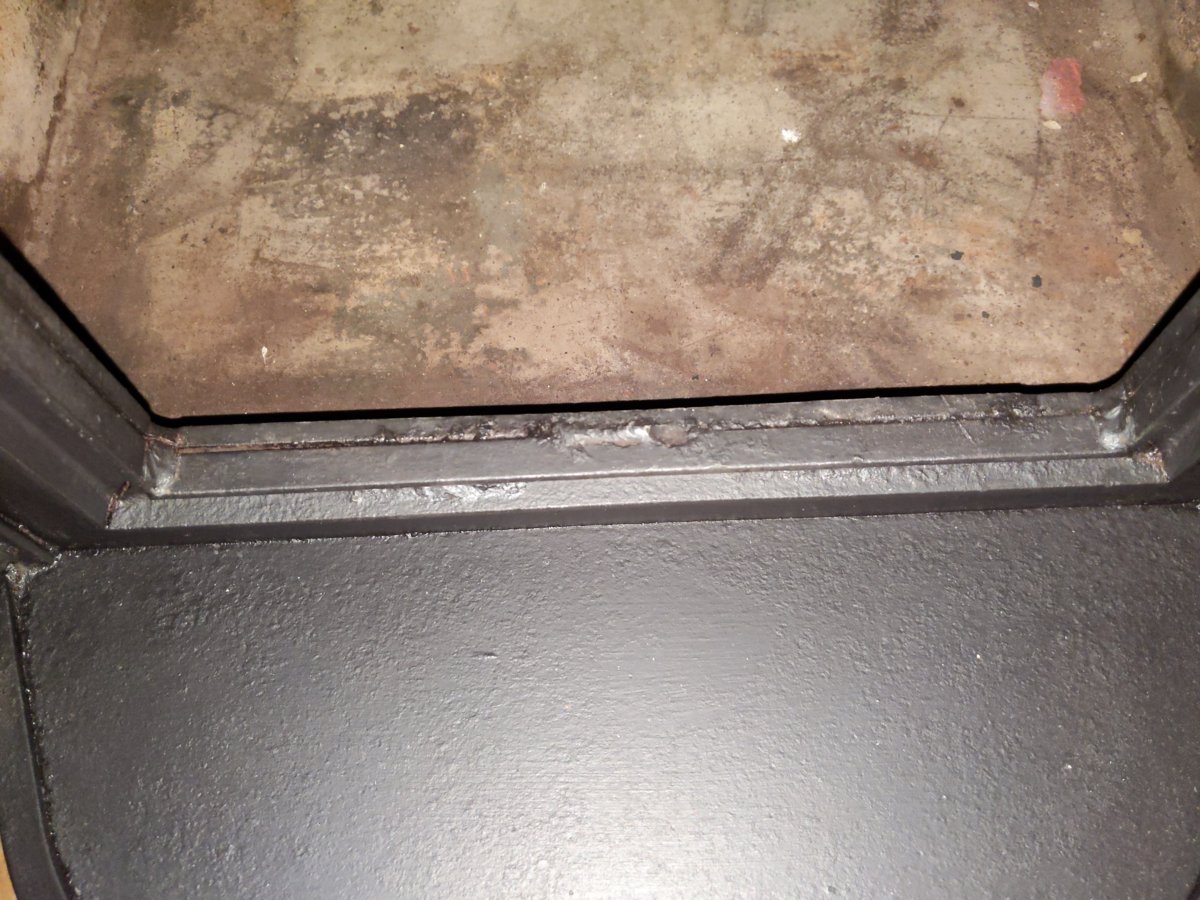

On my earliest Papa Bear with a 3-piece top and plain cast iron door, the channel iron is welded to the stove door opening with a short weld along the top center of the channel iron, and the same on all 4 sides, inside and outside. The corners look like they are slightly bowed away from the stove. The channel iron is cut into 4 separate pieces.

I believe this stove was built in early 1974, possibly from the first batch of usable cast iron doors.

This stove has no markings or numbers on it.

On my earliest Papa Bear with a 3-piece top and plain cast iron door, the channel iron is welded to the stove door opening with a short weld along the top center of the channel iron, and the same on all 4 sides, inside and outside. The corners look like they are slightly bowed away from the stove. The channel iron is cut into 4 separate pieces.

I believe this stove was built in early 1974, possibly from the first batch of usable cast iron doors.

This stove has no markings or numbers on it.

Last edited: