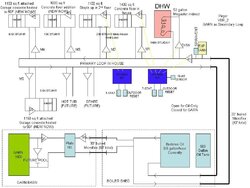

The GARN 1500 has arrived! Now it is is time to get it all set up. I will connect the GARN through a HX and plumbed as a secondary loop. Attached is a planned overall layout sketch.

I'd like to maximize the heat I can suck out of the GARN, so I'm thinking I'd like to size my HX to get the "closet approach" temperature I can, within reason. My heating is all radiant in slab, so water temperatures of 100 degree is all I really need. I plan to heat DHW though, so this is a different story. I'm hoping to can go down to 120F in the GARN...though the DHW might charge a bit slow with this relatively low temperature.

I'm looking at the flat plate units from Flat Plate, now GEA PHE Systems. It seems like the 5x12-80 plate should get me fairly close, and it seems that this is significantly oversized. My heating load is less than 100K/HR, plus the DHW. But I've also broken the bank here, so if I can save a bit of money, I'd like to hear it!

WHat I don't seem to understand though is the various models of 5x12 units from GEA. I see the "FP" series and the GBE series. Is the difference here primarily working pressure? The FP up to 450psi and the GBE at 232? Both obviously are way beyond what I need. I understand the MPN series is for pools/spas and the like.

I found the detailed specs for the FP series, but not the GBE series. I believe the GBE series is the "economy" model for typical heating needs?

I see the GBE 5x12-80 plate for about $600. I also see it doesn't have the mounting studs. Do folks typically suspend these exhangers in a homemade mount?

Can you heat these things up too fast and cause damage? If a circulator turns on and pumps 195 degree water from the GARN at 15 gpm, can this cause any damage? I'd think I'd heat up my primary loop very quickly at this rate. I have 1 1/4" microflex after the HX to the primary loop.

Thanks!

I'd like to maximize the heat I can suck out of the GARN, so I'm thinking I'd like to size my HX to get the "closet approach" temperature I can, within reason. My heating is all radiant in slab, so water temperatures of 100 degree is all I really need. I plan to heat DHW though, so this is a different story. I'm hoping to can go down to 120F in the GARN...though the DHW might charge a bit slow with this relatively low temperature.

I'm looking at the flat plate units from Flat Plate, now GEA PHE Systems. It seems like the 5x12-80 plate should get me fairly close, and it seems that this is significantly oversized. My heating load is less than 100K/HR, plus the DHW. But I've also broken the bank here, so if I can save a bit of money, I'd like to hear it!

WHat I don't seem to understand though is the various models of 5x12 units from GEA. I see the "FP" series and the GBE series. Is the difference here primarily working pressure? The FP up to 450psi and the GBE at 232? Both obviously are way beyond what I need. I understand the MPN series is for pools/spas and the like.

I found the detailed specs for the FP series, but not the GBE series. I believe the GBE series is the "economy" model for typical heating needs?

I see the GBE 5x12-80 plate for about $600. I also see it doesn't have the mounting studs. Do folks typically suspend these exhangers in a homemade mount?

Can you heat these things up too fast and cause damage? If a circulator turns on and pumps 195 degree water from the GARN at 15 gpm, can this cause any damage? I'd think I'd heat up my primary loop very quickly at this rate. I have 1 1/4" microflex after the HX to the primary loop.

Thanks!