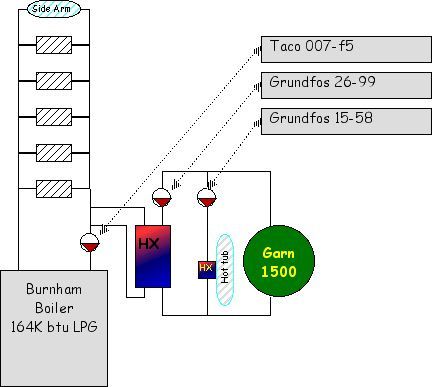

Hmmm... I think I like the earlier drawing a little better for our purposes. Let us start with the drawing you had in post #19, that I also quoted above....

In that drawing, I don't see ANY serious issues with the Garn side of the house HX... You could play with where the pumps are at, and how you have the hot tub plumbed in, but what you have drawn should work fine...

Where I saw issues is on the HOUSE side of the HX. As drawn in that picture, you would send all your circulation through the Burnham, and nothing through the HX, because you are tieing into the house loop with a pair of closely spaced tees, and don't have anything in the HX loop to make water flow through it.

For the purpose of this discussion, that entire ladder looking structure of the radiant flooring and sidearm exchanger could be considered as one big blob called "load" with two pipes coming out, supply and return... I don't see a need to change anything in the blob, but you need to do something to connect the HX and the Burnham to it, the question is what? The Burnham and HX can also be thought of as blobs that function as heat sources, with two pipes, one that gets cold water in, and the other hot water out.

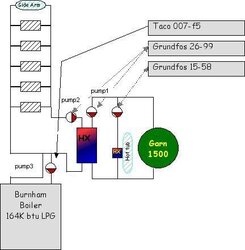

Now in the picture you just posted in #23, you have the HX drawn in differently, so that it is in the main loop along with the Burnham, so the water comes out of the pump, goes into the Burnahm, (I'm going to call it the BH after this...) out of the BH to the expansion tank and load supply (per the standard "pumping-away" guide this is wrong BTW, as the pump should be pushing AWAY from the ET, not towards it) through the load, into the HX, and from there back to the pump. This works, and would do the job, but you will be wasting a fair bit of energy keeping the BH hot, and pumping water through that added resistance when you don't have to. IF the Garn and the BH were both running at the same time, you would also be pulling heat out of the house loop and sending it to the Garn; but if the Garn pump was off, as it should be if the BH is on, you shouldn't have any flow on the Garn side of the HX, so you shouldn't lose a lot of heat there, but it puts extra pumping load on going through the HX when you don't need to.

I don't know which drawing reflects what you are actually doing, (I would note that the Garn side in the two drawings is also significantly different, but I am not going there in this post!), but since both drawings have problems, and either the fixes I'm proposing would solve both drawings, it doesn't matter...

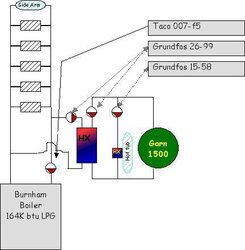

Let me go over the two ideas again.... Draw them both out and see if they make sense to you, if either or both don't, post what you came up with so I can make sure that you are drawing what I'm describing...

#1 Is to convert the house side into a primary/secondary system, with the load as the primary loop, and the BH and HX as independent secondary loops. To do this, disconnect the BH, and tie the supply and return of the house load together, moving the existing pump to the other side of the expansion tank while you are at it. Put in two pairs of closely spaced tees as well. Connect the BH and a second pump w/ flow check in a loop to one of the pair of tees, and the HX and a third pump to the other. These two new pumps can both be pretty small, size them to provide adequate flow around a loop consisting only of the BH or HX, the two tees, and the connecting pipes. Set up the controls so that when you have a call for heat, the load circ and the circ for whichever heat source is being used comes on, with the unused circ staying off...

#2 Is to put the two loads in parallel, so that you only have one pump on the house side, and add control valves so that you only get flow through the heat source that is being used. To do this one, move the pump to the other side of the expansion tank so that it pumps away from the tank into the house load. Put a T on the supply and return sides of the house load, and connect the cold water in sides of the BH and HX to the return of the house load, and the hot out sides to the supply side. Your pump now sends water through the house load and then splits the flow with some going through the BH and some through the HX, then brings them back together at the expansion tank to go back to the pump. Now, in order to choose which heat source you use, either put one zone valve in each of the lines to the HX and BH, or an A/B selector valve at either of the tees. Set the controls up so that on a call for heat, the house load pump turns on, the zone valve for the source you want is open, and the other closed (or the selector is in the right position), and you turn on the appropriate heat source...

Does that help?

Gooserider