wardk

Feeling the Heat

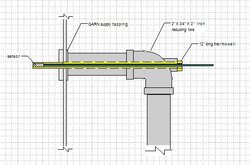

Hi Heaterman, I have a similar set up as Chris ,I am adding a Lp boiler to the system for backup. On Chris's system it looks like he has a valve in the supply line to bring his oil boiler off or on line. My question is can I continuously run my supply through my backup and have it light when the supply drops to a set temp.?I am putting the back up boiler in the Garn barn and am concerned about freezing if it's off line, it only holds 3gal of water so I was thinking the BTU loss would be minimal this way. Any input would be appreciated,The Alpha you see in between the expansion tank/air scoop and the 4 house zones circulates everything in the house. Given that the return is piped through the heat exchanger all the heat is picked up there when the Garn is running. When the Garn is off the oil boiler (and it's own circ) are heating/moving the water through the closely spaced tees to the left of the air scoop.

Chris has the oil boiler isolated from the house loop via those closely spaced tees to let it go cold when not needed. This is easily done with the appropriate relays.

BTW Chris, a tip of my hat to you for a really nice piping layout. That's about as good as it can be done and the owner is going to enjoy great economy and service from that design. Kudo's to you and a couple of Huzzah's besides