Over the weekend we purchased a near new US Stove pellet stove for our house. We are planning on installing it in the basement and using an existing hole/thimble in the concrete wall for the flue pipe to exit. The question I have is that in reading the manual it says not to have more than 180 degrees of bends in the pipe...that being said here is my dilema. The pipe exits the stove approx 18 inches from the floor straight out of the back...and my thimble in the concrete wall is about 8 feet above that. I have no existing flue pipe outside. Would it be feasible to come out of the back of the stove with a 45, then straight up to another 45 going into the thimble...then a short piece of straight into a T, then up?? That's still 180 degrees, but its the only thing I can come up with at the moment. Worst part of it is, I am going to have to move the stove further out from the wall to be able to do the 45's. Am I on the right track? Thanks in advance!!

Getting ready to install pellet stove, need help with flue pipe questions

- Thread starter oleladyneedsheat

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

festerw

Minister of Fire

Why not put the clean out tee off the back of the stove go straight up to a 90 degree and then straight out the thimble? My stove has been set up like this for 4 years with no problem.

I

imacman

Guest

Are you installing it in the basement ONLY because of the existing thimble? Are you going to try heating the upstairs, or just the basement w/ the stove? These stoves should really be installed in the room/area you mainly want the heat.

When you say t out of the back, then straight up to another 90, then out....do you mean run it straight out from the wall and leave it with no up pipe outside?

I am putting it in the basement for 4 reasons actually....one I have a perfect spot for it and the hole is already there, two it does have a duct blower assembly on it and it will connect to the truck line directly above where the stove sits, thirdly she is in the basement 90 percent of the time in the winter, and lastly, I can put two pallets of fuel in my lower garage with my forklift and have them close when its ready for reload.

I am putting it in the basement for 4 reasons actually....one I have a perfect spot for it and the hole is already there, two it does have a duct blower assembly on it and it will connect to the truck line directly above where the stove sits, thirdly she is in the basement 90 percent of the time in the winter, and lastly, I can put two pallets of fuel in my lower garage with my forklift and have them close when its ready for reload.

bjr23

Member

I'm a pellet stove Newbie and two weeks ago I did the same thing only I bought (stove only, no pipe) and installed an old Whitfield in my basement and the installation said 270 degrees and I just met that by venting direct right outside the wall. What I think you'll find is the really bad part is the price of that twist lock pellet stove pipe. Lowes sold a Simpson horizontal kit with 5-1' -90 deg 1- and a cleanout tee and a wall Thimble and horizontal exhaust termination for $200 and I had get extra 3' and extra 90 deg. I then went a dedicated stove supply and bought what they called a adjustable pipe (one end made slide over a standard pipe) with yet another 1' pipe. Now like I said all this does is get me up the basement wall and horizontally to the outside. Total cost $400 for piping. I did get 2 bags of pellets and quart of jelly fire starter, too. I'm not saying to disregard the manufacturer totally but I'd go ahead and make up connections that suit you and you'll find out in a hurry if it's not right (lazy flame and sooting). I'm willing to bet though that one extra 90 won't hurt in the least. My used stove happened to be totally plugged behind the fire brick and had the wrong pressure switch installed. Once I got a few things sorted out it works very well and heats the basement great. I didn't seal glue or tape any fittings because I wanted to be able to change things if needed and especially the connection to the back of the stove as I had to dissconnect and turn the stove around to work on it a few times. I haven't had smoke leakage from any joints either. I seen a tip on the clean out tee and that was to put some antisieze on the removalble cap for easy removal. I'd get a CO2/fire alarm (Lowes about $35) installed down there also. Oh yeah, work this site heavy 'cause there's some good info here, I do. bjr23

But if I direct vent (guess that is the term for no outside vertical pipe) I am only about 4 inches from ground level...wonder what that will do if we get alot of snow

hossthehermit

Minister of Fire

oleladyneedsheat said:But if I direct vent (guess that is the term for no outside vertical pipe) I am only about 4 inches from ground level...wonder what that will do if we get alot of snow

I'd go with the 45's, and some vertical outside, rather than take a chance on getting covered w/ snow. BUT, that's just MY opinion.

bjr23

Member

I had nearly 24" to the ground, but, you're almost in the same boat as me. I was starting to think "How badly do I need this pellet stove" as I was lookin' at 'nother $300 to go on up thru or around the eves (roof thimble and possibly more 45's) for 10' vertical run, and probably at the wall penetration go to 4" pipe. I was told once that "on a ship the riggin' cost more than the hull". We got into the basic stove reasonbly, but, the pipping nearly killed the deal. It'll have to be your call. bjr23

Yeah it sounds like it....we bought the stove for 900, but had to drive 413 miles round trip to get it.

So I have been reading away on here, a pellet stove does not need draught like a normal wood stove I take it.

So I have been reading away on here, a pellet stove does not need draught like a normal wood stove I take it.

Does anyone have any pics of something similar to what I am trying to do? Direct vent outside pics would be awesome!

thanks

thanks

bjr23

Member

Zooblers have some decent venting diagrams, check out their site. As near as I can tell pellet stoves have their own double wall pipe and they say for pellet stoves (maybe an insurance standards thing, I dunno). Simpson seems to be the brand of choice with their twist lock. I don't know of any other brands or manufacturers. bjr23

I

imacman

Guest

oleladyneedsheat said:......a pellet stove does not need draught like a normal wood stove I take it.

Technically no, it doesn't, since the combustion blower takes care of blowing the exhaust outside, but in the event of a power outage, it's nice to have some vertical to help draw out the smoke when the stove stops.

Thanks alot....I am still trying to figure out exactly how I am gonna do it....I'd like to have the cleanout inside, but that seems impossible when using 45's

I

imacman

Guest

oleladyneedsheat said:Thanks alot....I am still trying to figure out exactly how I am gonna do it....I'd like to have the cleanout inside, but that seems impossible when using 45's

You could probably use 90's, plus about 3' of vertical outside if you go to 4" pipe.

The EVL for (3) 90's = 15, plus another .5 for each foot of straight pipe. Anything over EVL of 15 requires 4" pipe.

Ok cool, thanks for that

So use a reducer into the back of the stove, connect to a t, up 7 feet to another 90, through the wall to another 90, then up 3 feet? Am I picking up what you are putting down? lol

So use a reducer into the back of the stove, connect to a t, up 7 feet to another 90, through the wall to another 90, then up 3 feet? Am I picking up what you are putting down? lol

I

imacman

Guest

oleladyneedsheat said:Ok cool, thanks for that

So use a reducer into the back of the stove, connect to a t, up 7 feet to another 90, through the wall to another 90, then up 3 feet? Am I picking up what you are putting down? lol

Yes, assuming your stove has a 3" outlet, from that to 3" to 4" appliance adapter, then cleanout-T, up 7' to 90, then out, another 90, then up 3' to cap.

Yeah I think it does, haven't put a tape on it yet but it looks small. Now, the last question I have is about where it goes through the wall....I have what appears to be a 6 inch hole surrounded by a clay thimble right now. I was thinking I would prolly have to install a correct 4 inch thimble kit through the clay, or bust the clay out if the hole wasn't big enough. I think the hole would be around 8 inches if I was able to get the clay out of it. Would you use a metal thimble for this? If so, where do I find one for a 9 inch thick wall?

bjr23

Member

I have 12-1/4" thick walls and I had use a piece of 8" metal HVAC ducting to fill in between the thimble halves. A piece of old stove pipe or HVAC duct whatever easiest to cut to length with tin snipes. Mine didn't fit tight around the thimble peices (thimble pieces 7" and duct pipe 8") but I thought that would be okay anyways, it's what I did. bjr23

I

imacman

Guest

oleladyneedsheat said:Yeah I think it does, haven't put a tape on it yet but it looks small. Now, the last question I have is about where it goes through the wall....I have what appears to be a 6 inch hole surrounded by a clay thimble right now. I was thinking I would prolly have to install a correct 4 inch thimble kit through the clay, or bust the clay out if the hole wasn't big enough. I think the hole would be around 8 inches if I was able to get the clay out of it. Would you use a metal thimble for this? If so, where do I find one for a 9 inch thick wall?

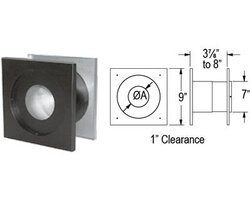

Taking out the clay thimble seems like that's how you'd have to do it. The thimble for 4" pipe is approx. 7" dia.

The thimble will also extend to a max. of 8" long, so as bjr23 mentioned above, you'll have to come up with a piece of regular stove pipe or hvac ductwork to make up the other 1" or so.

I don't know what brand of pipe you're planning on buying, but here's a diagram of a Simpson thimble:

Attachments

I will buy whatever everyone thinks is the best for my application. Is there a certain online place I should use over another?

I

imacman

Guest

oleladyneedsheat said:I will buy whatever everyone thinks is the best for my application. Is there a certain online place I should use over another?

These are the 2 places that I use, and they both sell Simpson DuraVent. To make sure you don't have leak problems, make sure you ask for DuraVent Pro piping. Eric at Kinsman Stoves is a great guy, and has good prices.....he is also a member on this forum.

If he is out of something, and you don't want to wait, try the other link for Dynamite Buys.com. Nice people, good prices, fast (free) shipping:

http://kinsmanstoves.com/

www.dynamitebuys.com/

krooser

Minister of Fire

Here's my horizontal vent...

I'm not sure you'll need a thimble when going thru a concrete wall... maybe so if you need it seal it from the elements.

The same for a clean-out. Pellet stoves don't accumulate a lot of creosote like wood stoves... a flexible brush can clean the vent pipe pretty well and we have the patented "leaf blower trick" here on the forum which does a great job of cleaning both the stove and the vent pipe. Since you only have 4" clearance to the ground you'll need to run a verticle vent, too, but you don't need to run it more than 5' up or so.... pellet stoves don't need a lot of draft like a woodstove.

Good luck.

I'm not sure you'll need a thimble when going thru a concrete wall... maybe so if you need it seal it from the elements.

The same for a clean-out. Pellet stoves don't accumulate a lot of creosote like wood stoves... a flexible brush can clean the vent pipe pretty well and we have the patented "leaf blower trick" here on the forum which does a great job of cleaning both the stove and the vent pipe. Since you only have 4" clearance to the ground you'll need to run a verticle vent, too, but you don't need to run it more than 5' up or so.... pellet stoves don't need a lot of draft like a woodstove.

Good luck.

bjr23

Member

That picture reminded me of something about how far from a window should the exhaust be. I think there's a recommended distance from windows both a vertical distance and a horizontal distance. If there's a web site for your manufacturer you might see about this. bjr23

krooser

Minister of Fire

bjr23 said:That picture reminded me of something about how far from a window should the exhaust be. I think there's a recommended distance from windows both a vertical distance and a horizontal distance. If there's a web site for your manufacturer you might see about this. bjr23

It meets code... that's why I have the additional 2' vent pipe added. I think the code is 38" from the end of the pipe to any opening window... it's measured in a straight line from the exhaust to the edge of the window.

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 2K

- Replies

- 2

- Views

- 183

- Replies

- 4

- Views

- 525

- Replies

- 2

- Views

- 896