How much do side/back heatshields affect the heat output of a freestanding wood stove?

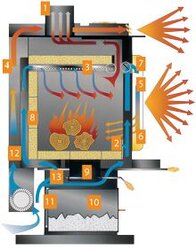

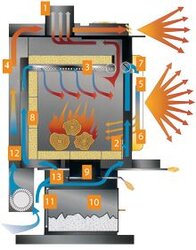

One of the stoves I'm looking at is the Napoleon 1100P, and it has what looks like insanely close installation clearances, due no doubt to the integral heat shields (that channel cold air around the firebox and out the front louvers; a clever design, I think) on the sides.

Is this likely to inhibit the tranfer of the firebox heat to the room?

One of the stoves I'm looking at is the Napoleon 1100P, and it has what looks like insanely close installation clearances, due no doubt to the integral heat shields (that channel cold air around the firebox and out the front louvers; a clever design, I think) on the sides.

Is this likely to inhibit the tranfer of the firebox heat to the room?