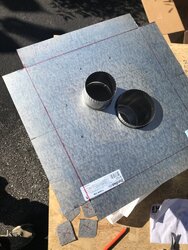

I'm at a loss and can't figure out how to mount the Duravent Prairie Termination Cap (at $250.00) to the (old and cracked) clay liner in my chimney. It has the OAK 3" hookup in the cap, so up and down the chimeny with a 4" and 3".

The cap has a flat piece of metal. I guess my options are:

Bend the sheet metal, which looks nearly impossible the way the cap is put together. but then I still have to figure out how to attach it to the clay liner. The 1968 liner is heavily used and sooty. I suspect it, even if I could bend it, that any drilling to attach it would just fracture the liner. If you think bending is the only way, any ideas on what to use to bend it?

I' could technically glue it to the clay liner, but it is sooty. I'm concerned that high winds would rip it off after the glue fails or due to freezing/thawing/age/clay liner flaking off.

It is a high wind area (aren't all chimneys, really).

Anybody got any ideas?

Basically, if I could figure this out I could get my install done. In the meantime, stove and everything is in the garage waiting.

Thanks!

The cap has a flat piece of metal. I guess my options are:

Bend the sheet metal, which looks nearly impossible the way the cap is put together. but then I still have to figure out how to attach it to the clay liner. The 1968 liner is heavily used and sooty. I suspect it, even if I could bend it, that any drilling to attach it would just fracture the liner. If you think bending is the only way, any ideas on what to use to bend it?

I' could technically glue it to the clay liner, but it is sooty. I'm concerned that high winds would rip it off after the glue fails or due to freezing/thawing/age/clay liner flaking off.

It is a high wind area (aren't all chimneys, really).

Anybody got any ideas?

Basically, if I could figure this out I could get my install done. In the meantime, stove and everything is in the garage waiting.

Thanks!