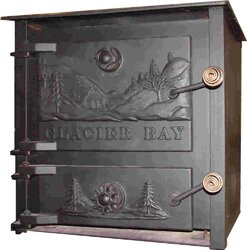

I need to identify whether a stove is designed for Wood or Coal.

I understand that some can be used for both however they are not best at both. Coal needs air from bottom, wood needs supply from top. Other varriables apply probably. The stove in question is an old Glacier Bay fireplace insert. It has a solid bottom door with an air control knob and an ash pan. The Top also has a solid door with an air control knob. Between the bottom and top there are grates which operate via a removable handle. Firebrick surrounds the combustion chamber. Brackets in sides to accomodate a baffle for the top (this is missing so I don't know the measurements to make a new one yet). The baffle would sit at an angle from front to back at appox 40 degrees (guess). 8" round hole in top back half for exhaust combustion air. No blowers. firebox approx.18" x 17" with brick installed. Baffle should be approx. 20.5" wide by ??? deep. Room circulation air enters through bottom opening almost entire width of unit but only approx. 1" high, leaves through same design at top front of unit. Has legs but they are removable. Has removable heavy plates that can lay on top of shaker grates to basically close off bottom.

My unknowledgeable thought is this is designed for coal but by using the plates and air control knobs it can also function for wood.

I have excellent detailed pictures, having difficulty posting here will post later if possible and if someone desires.

Also is there a place I can purchase a blower for it. As the opening in the bottom is so small (the door overhangs the opening a little) and placing a blower on top has the heat problems that may damage unit. I'm not sure if it is feasible.

I understand that some can be used for both however they are not best at both. Coal needs air from bottom, wood needs supply from top. Other varriables apply probably. The stove in question is an old Glacier Bay fireplace insert. It has a solid bottom door with an air control knob and an ash pan. The Top also has a solid door with an air control knob. Between the bottom and top there are grates which operate via a removable handle. Firebrick surrounds the combustion chamber. Brackets in sides to accomodate a baffle for the top (this is missing so I don't know the measurements to make a new one yet). The baffle would sit at an angle from front to back at appox 40 degrees (guess). 8" round hole in top back half for exhaust combustion air. No blowers. firebox approx.18" x 17" with brick installed. Baffle should be approx. 20.5" wide by ??? deep. Room circulation air enters through bottom opening almost entire width of unit but only approx. 1" high, leaves through same design at top front of unit. Has legs but they are removable. Has removable heavy plates that can lay on top of shaker grates to basically close off bottom.

My unknowledgeable thought is this is designed for coal but by using the plates and air control knobs it can also function for wood.

I have excellent detailed pictures, having difficulty posting here will post later if possible and if someone desires.

Also is there a place I can purchase a blower for it. As the opening in the bottom is so small (the door overhangs the opening a little) and placing a blower on top has the heat problems that may damage unit. I'm not sure if it is feasible.

.

.