From Adios Pantalones on another thread:

My answer:

Yes, you are correct, efficiency drops as MC gets very low (I'm someone who has actually provided this documentation here before), but at what point does it begin to turn downward? Many stove companies have begun hinting that firewood can be too dry (although they all fail to specify the magic number), but their concern seems to be in avoiding overfiring (a warranty issue) rather than improved combustion efficiency. While hotter burns with any wood will usually be cleaner and achieve greater combustion efficiency, overall heating efficiency can decline under these conditions since more hot air is allowed up the flue.

All of the studies that I have seen were done pre-EPA Phase I, and they seemed to show a general trend for combustion efficiency to peak between 25-30% MC, for heat transfer efficiency to drop steadily as MC increases, and for overall heating efficiency to occur at about 20% MC dry-basis (see chart below).

I have to wonder how have these figures have changed (or if they've changed at all) with the advent of modern technology? Therefore, I still feel this should be studied under controlled conditions.

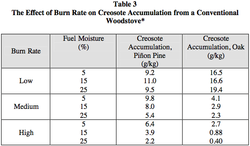

BTW it has been experimentally determined that there is an extremely high correlation between particulate matter produced and creosote formation under similar burn conditions. Obviously, hotter burns and more excess air aren't similar burn conditions, but study after study have shown that very dry woods (both hardwood and softwoods) produce more measurable creosote under all burn conditions, at least in the old stoves (with fireplaces the opposite is true due to the dilution effect of the large mass airflow up the flue). If this has been totally reversed by the new technologies, it seems that this should be well documented, but I have not been able to find any studies that address this question. My instincts tell me that there has been no reversal of these trends, but merely a shift in the location of the peaks (likely to the left, or at lower MCs).

Regardless, we are all stewards of the environment, so clean burning should be the primary goal rather than just reduced creosote formation in the chimney. Should we aim for greater overall efficiency (more usable heat per cord of wood) or greater combustion efficiency (cleaner air)? At what MC are each of these goals achieved in modern stoves?

It’s documented that efficiency goes DOWN at really low MC, and I think that’s the reason Batt. particles need a cool surface or extra water to condense and form problematic creosote, so while emissions *may* go up, a hotter fire with soft wood (which is often the case) seems to compensate for any increase in emissions; at least it does not directly follow that increased particle necessarily means more creosote.

My answer:

Yes, you are correct, efficiency drops as MC gets very low (I'm someone who has actually provided this documentation here before), but at what point does it begin to turn downward? Many stove companies have begun hinting that firewood can be too dry (although they all fail to specify the magic number), but their concern seems to be in avoiding overfiring (a warranty issue) rather than improved combustion efficiency. While hotter burns with any wood will usually be cleaner and achieve greater combustion efficiency, overall heating efficiency can decline under these conditions since more hot air is allowed up the flue.

All of the studies that I have seen were done pre-EPA Phase I, and they seemed to show a general trend for combustion efficiency to peak between 25-30% MC, for heat transfer efficiency to drop steadily as MC increases, and for overall heating efficiency to occur at about 20% MC dry-basis (see chart below).

I have to wonder how have these figures have changed (or if they've changed at all) with the advent of modern technology? Therefore, I still feel this should be studied under controlled conditions.

BTW it has been experimentally determined that there is an extremely high correlation between particulate matter produced and creosote formation under similar burn conditions. Obviously, hotter burns and more excess air aren't similar burn conditions, but study after study have shown that very dry woods (both hardwood and softwoods) produce more measurable creosote under all burn conditions, at least in the old stoves (with fireplaces the opposite is true due to the dilution effect of the large mass airflow up the flue). If this has been totally reversed by the new technologies, it seems that this should be well documented, but I have not been able to find any studies that address this question. My instincts tell me that there has been no reversal of these trends, but merely a shift in the location of the peaks (likely to the left, or at lower MCs).

Regardless, we are all stewards of the environment, so clean burning should be the primary goal rather than just reduced creosote formation in the chimney. Should we aim for greater overall efficiency (more usable heat per cord of wood) or greater combustion efficiency (cleaner air)? At what MC are each of these goals achieved in modern stoves?