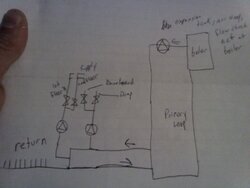

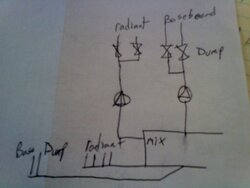

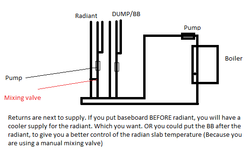

This is what I made tonight. This is for a friend of mine. Before the mixing valve we have a dump loop and HWB. after the mix valve is two zones, first and second floor heat (radiant in floor). There is only two 300 loops for each zone. The gaps between the pipes is where the pumps will be going. This is going to be set up as a primary secondary loop. Since I am zoning with valves and not pumps do I need close T's or does the distance not matter? I didnt solder the offset yet.