Hi all! My husband and I are relatively new to burning (this is our second year) and we love it! Nothing beats wood heat!

However, my mom bought a new home a few months ago and got a new Lopi Next Gen Fyre insert (medium ).

The issue is that it’s really struggling to put off any heat. She’s ran it all day long and it won’t even raise the temperature in her house one degree. In fact, it won’t even keep the central heat from coming on!

We get it started with some pine, then keep it running with well-seasoned oak (we’ve used a moisture meter and it’s pretty dry).

It takes about an hour for the blower to come on. She burns with the air intake fully open to try and keep it burning warm.

Her house is 2,400 sq ft, so I know that it wouldn’t effectively heat the entire house well (the insert is rated for 2,000 sq ft). But I would think it would at least raise the temperature in the living room where the stove is?

She does have pretty high ceilings (I think 20 feet), but she does have a really big fan blowing the correct direction to help push the heat back down. The flue pipe goes straight up the chimney, no bends, about 20 feet.

Any ideas on why it’s struggling so much? She thinks it’s because she “doesn’t know how to do it right.” But I’m wondering if it’s maybe a stove problem?

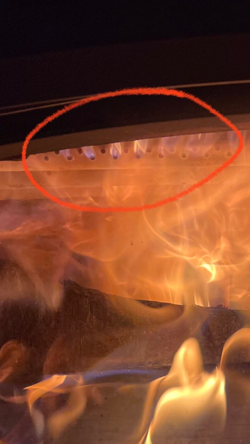

Added two pictures of the stove setup for reference.

Thanks for the help!

However, my mom bought a new home a few months ago and got a new Lopi Next Gen Fyre insert (medium ).

The issue is that it’s really struggling to put off any heat. She’s ran it all day long and it won’t even raise the temperature in her house one degree. In fact, it won’t even keep the central heat from coming on!

We get it started with some pine, then keep it running with well-seasoned oak (we’ve used a moisture meter and it’s pretty dry).

It takes about an hour for the blower to come on. She burns with the air intake fully open to try and keep it burning warm.

Her house is 2,400 sq ft, so I know that it wouldn’t effectively heat the entire house well (the insert is rated for 2,000 sq ft). But I would think it would at least raise the temperature in the living room where the stove is?

She does have pretty high ceilings (I think 20 feet), but she does have a really big fan blowing the correct direction to help push the heat back down. The flue pipe goes straight up the chimney, no bends, about 20 feet.

Any ideas on why it’s struggling so much? She thinks it’s because she “doesn’t know how to do it right.” But I’m wondering if it’s maybe a stove problem?

Added two pictures of the stove setup for reference.

Thanks for the help!