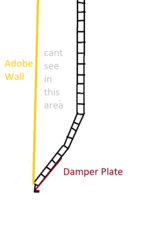

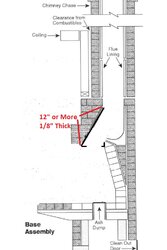

Looking into installing a freestanding stove on an existing fireplace hearth and looking at all options. Making a small, partial circle, notch into the lintel would provide extra clearance. The lintel is very heavy duty. It has a large thick plate going up into the flu and across the entire fireplace. It seems that making a small notch would not effect it structurally.

Is it acceptable to make a 3/4" notch in the lintel per the attached pics?

Ignore the bolt as it supports a block plate. A new bolt(s) can be re-tapped again into the lintel as needed.

Is it acceptable to make a 3/4" notch in the lintel per the attached pics?

Ignore the bolt as it supports a block plate. A new bolt(s) can be re-tapped again into the lintel as needed.

Last edited by a moderator: