I have a Tarm OT-50 that I installed about 5 years ago. The first year I used wood for the winter, and the next couple years I used coal for the winter. During the summer I have used oil because I do not have any thermal storage. For convenience sake, and because it was cheap, I used oil all last winter. At the end of the winter the oil burner quit on me and I had to have it serviced. I had not serviced it since i originally serviced it when I installed it. Normally during oil operation, I move the damper in the top of the boiler to redirect the air flow as shown on the sticker on the boiler. I also move the chain down on the damper so it stays closed. Previously during oil operation I have seen a light coating of black inside the boiler and that is all.

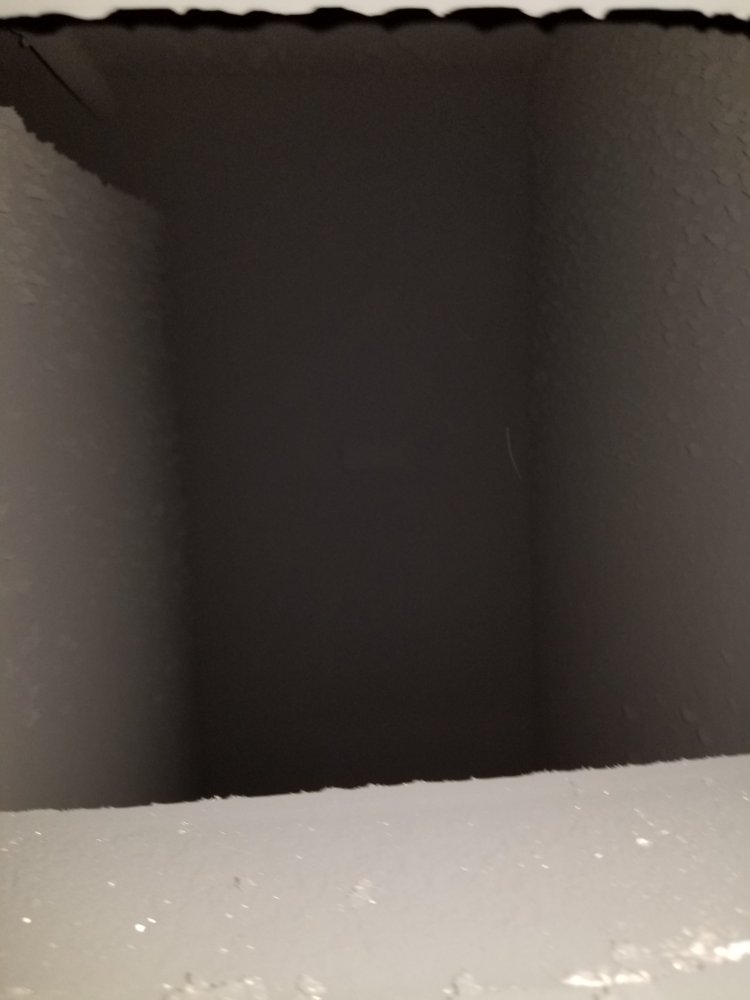

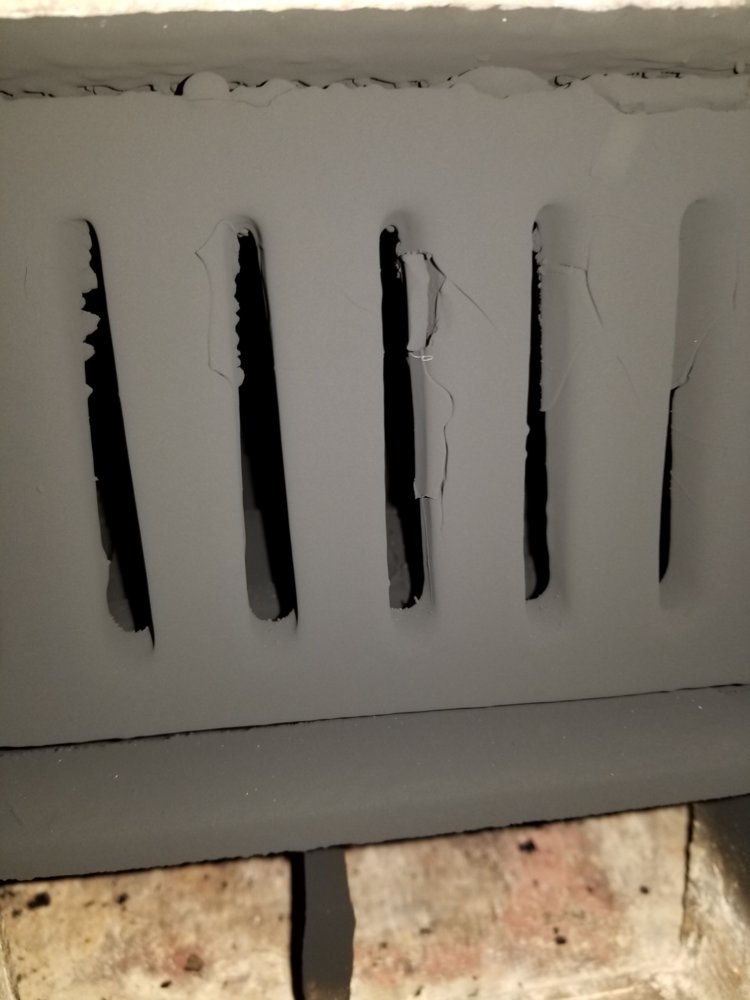

Now for my issue and my question: I had the boiler serviced in April when the burner would not light. The service tech said the electrodes were burned back pretty far and the nozzle was gunked up. About 3 weeks ago it died on me again. When I opened the boiler I saw a thick black coating on the inside of the boiler. It was at least 1/4 inch think. I thoroughly cleaned the boiler, and then I switched it over to run off of coal, and I have been using coal since.

Is this much build up normal for a boiler like mine running on oil?

I noticed a difference when the boiler lights. Before servicing you could hear it light and hear the damper jump when lighting. After servicing it ran very quiet and you would not hear the damper jump when it lit. What is considered normal operation?

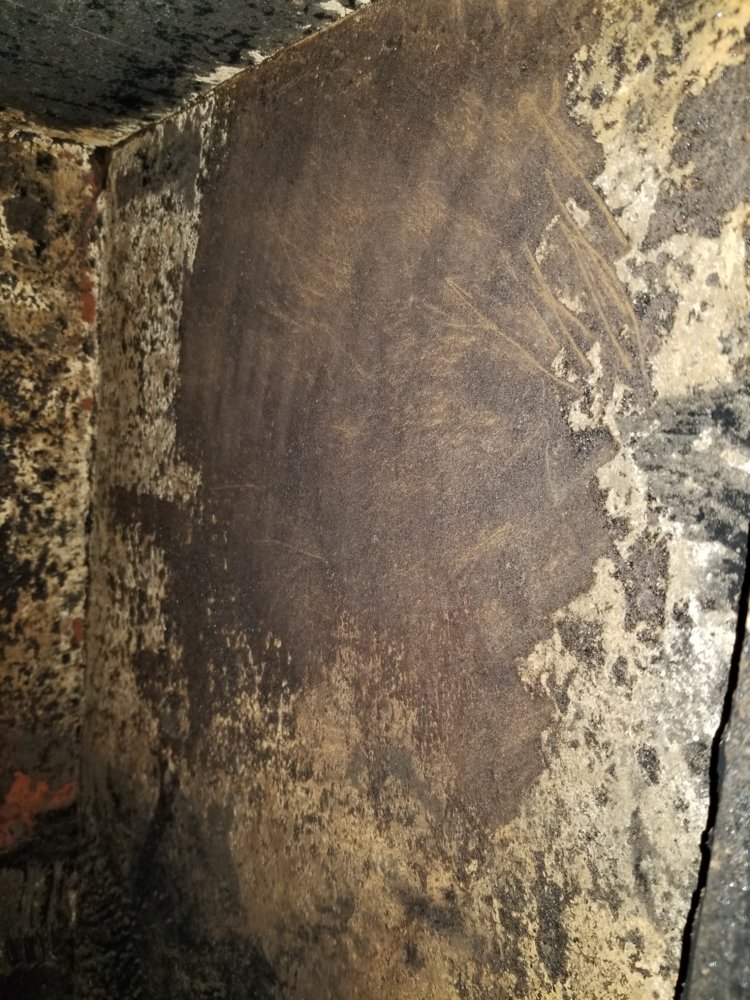

Underneath the soot buildup was a layer of white colored buildup that was tough to get off, but if I used a putty knife with an edge on it, I could get it to come off. Is this from burning wood or coal, and then oil after, or is this produced by the oil burning? Is this normal when burning oil?

I really don't know what to expect when burning oil in a multifuel boiler. Was my boiler serviced correctly originally and it supposed to be a little loud? or was it better the 2nd time and its supposed to be quiet? How much soot buildup is acceptable in a boiler like mine? From my experience I have found several people that say they have experience servicing Tarm boilers, but it seems to me like they all have their own ways of tweaking them. I just don't know what is right and what to expect. Should I call back the guy that serviced it 6 months ago and give him another chance? Should I try to find the guy that serviced it originally and give him another shot? Or should I try to find someone else?

Here are the pictures of my boiler before and during my cleaning:

Now for my issue and my question: I had the boiler serviced in April when the burner would not light. The service tech said the electrodes were burned back pretty far and the nozzle was gunked up. About 3 weeks ago it died on me again. When I opened the boiler I saw a thick black coating on the inside of the boiler. It was at least 1/4 inch think. I thoroughly cleaned the boiler, and then I switched it over to run off of coal, and I have been using coal since.

Is this much build up normal for a boiler like mine running on oil?

I noticed a difference when the boiler lights. Before servicing you could hear it light and hear the damper jump when lighting. After servicing it ran very quiet and you would not hear the damper jump when it lit. What is considered normal operation?

Underneath the soot buildup was a layer of white colored buildup that was tough to get off, but if I used a putty knife with an edge on it, I could get it to come off. Is this from burning wood or coal, and then oil after, or is this produced by the oil burning? Is this normal when burning oil?

I really don't know what to expect when burning oil in a multifuel boiler. Was my boiler serviced correctly originally and it supposed to be a little loud? or was it better the 2nd time and its supposed to be quiet? How much soot buildup is acceptable in a boiler like mine? From my experience I have found several people that say they have experience servicing Tarm boilers, but it seems to me like they all have their own ways of tweaking them. I just don't know what is right and what to expect. Should I call back the guy that serviced it 6 months ago and give him another chance? Should I try to find the guy that serviced it originally and give him another shot? Or should I try to find someone else?

Here are the pictures of my boiler before and during my cleaning: