First post after lurking for many years.

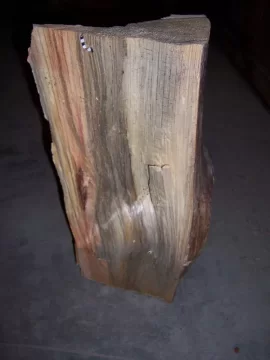

I heat primarily with wood, but in the past have cut mostly small fir rounds and split with an axe. I made the mistake (or had the good fortune) of making friends with a local arborist. I told him I would take all the logs he wants to drop off since I could use the firewood. Now I have a pile of oak logs next to my workshop with no way to split them. These things are monsters. The biggest one is 3 feet across and most are in the 18 to 24 inch range. Hammering in wedges is hopeless. It has been difficult even moving them or bucking into smaller chunks with my 20" chainsaw. The log splitter I borrowed from a friend hardly makes a dent in the smaller logs. Not sure, but I would suspect his splitter was 18 to 20 ton.

My plan at the moment is to head over to the local farm store and get one of their Black Diamond 37 ton splitters and get to work on these logs. It appears I will have a pretty continuous supply of logs from this arborist, so buying a splitter makes sense. It is a great thing to have so much free firewood, but I need to ramp up my equipment to deal with it.

Am I on the right track, or can someone suggest a better plan?

I heat primarily with wood, but in the past have cut mostly small fir rounds and split with an axe. I made the mistake (or had the good fortune) of making friends with a local arborist. I told him I would take all the logs he wants to drop off since I could use the firewood. Now I have a pile of oak logs next to my workshop with no way to split them. These things are monsters. The biggest one is 3 feet across and most are in the 18 to 24 inch range. Hammering in wedges is hopeless. It has been difficult even moving them or bucking into smaller chunks with my 20" chainsaw. The log splitter I borrowed from a friend hardly makes a dent in the smaller logs. Not sure, but I would suspect his splitter was 18 to 20 ton.

My plan at the moment is to head over to the local farm store and get one of their Black Diamond 37 ton splitters and get to work on these logs. It appears I will have a pretty continuous supply of logs from this arborist, so buying a splitter makes sense. It is a great thing to have so much free firewood, but I need to ramp up my equipment to deal with it.

Am I on the right track, or can someone suggest a better plan?