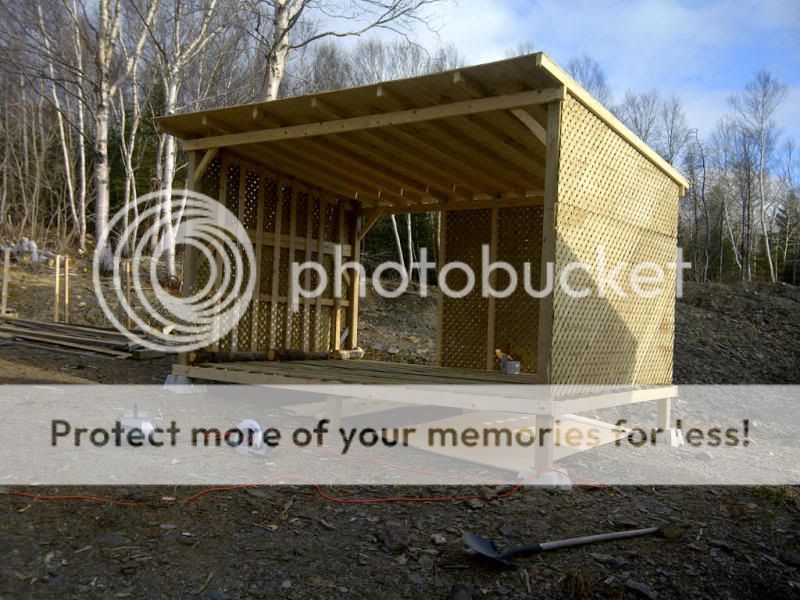

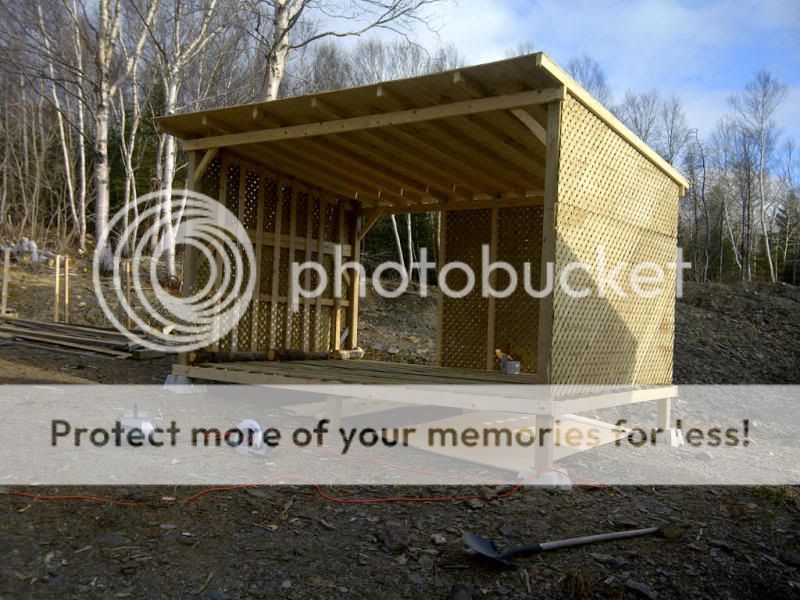

This thing is essentially finished just a few things left to do. The location that it is in gets a great deal of wind, good for drying but I am debating on how to finish the front and back. For the front I was going to add 2 more sheets of lattice on each end and leave the middle open, but should I sheet up the back completely? BTW it measures roughly 12 x 8 with the roof going from approx 8' down to 7' in the back. Should hold approx 5 cord. Back to the question at hand, how would you finish the front and back?