Good day, All.

Heading into wood burning season, I'm wrapping up a bit of a refurb on my Blaze King Princess Insert (PI 1010A). The BK is the main heat source in my single level 1400 sq ft home, backed up by central heat - During the cold winter months, the BK is typically burning 24/7. I grew up with non-cat wood heat, and I have been very impressed with the Blaze King experience so far. I recently pulled the insert from it's home in the fireplace area to clean accumulated soot from above the block off plate, replace the bypass gasket (which was completely compressed), I'll replace some damaged fire bricks, and the big ticket item is replacing the combustor with a new Midwest Hearth metal combustor (model MH-63M).

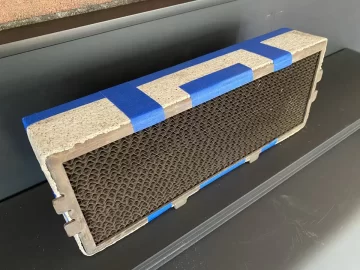

The BK is back in final position and I'm trying to install the brand new metal combustor to complete the refurb... I CAN NOT GET THIS SUCKER PUSHED INTO PLACE. I've installed the new interam gasket using single layer masking tape, including around the four sides of the inside edge, to avoid letting the gasket material from snagging during installation. The metal frame/dome is completely clean and free of deposits... very smooth to the touch. This model has the thin bypass retainer clips on the left and right sides and are properly installed. Comparing measurements of the original ceramic combustor and the new metal one, there is no notable difference - the new one doesn't seem too big or out of shape. I've made multiple attempts to press the new metal combustor into place and there's just way too much friction. Using my hands, I've strained trying to press it evenly into the dome frame, but can only make it about 3/4" until it's stuck. I carefully pull it back out, fix the tape and puckering edges of the gasket. What am I missing? Any pro tips to get this new combustor seated? I wasn't expecting it to be so tight.

Thanks for any recommendations!

Heading into wood burning season, I'm wrapping up a bit of a refurb on my Blaze King Princess Insert (PI 1010A). The BK is the main heat source in my single level 1400 sq ft home, backed up by central heat - During the cold winter months, the BK is typically burning 24/7. I grew up with non-cat wood heat, and I have been very impressed with the Blaze King experience so far. I recently pulled the insert from it's home in the fireplace area to clean accumulated soot from above the block off plate, replace the bypass gasket (which was completely compressed), I'll replace some damaged fire bricks, and the big ticket item is replacing the combustor with a new Midwest Hearth metal combustor (model MH-63M).

The BK is back in final position and I'm trying to install the brand new metal combustor to complete the refurb... I CAN NOT GET THIS SUCKER PUSHED INTO PLACE. I've installed the new interam gasket using single layer masking tape, including around the four sides of the inside edge, to avoid letting the gasket material from snagging during installation. The metal frame/dome is completely clean and free of deposits... very smooth to the touch. This model has the thin bypass retainer clips on the left and right sides and are properly installed. Comparing measurements of the original ceramic combustor and the new metal one, there is no notable difference - the new one doesn't seem too big or out of shape. I've made multiple attempts to press the new metal combustor into place and there's just way too much friction. Using my hands, I've strained trying to press it evenly into the dome frame, but can only make it about 3/4" until it's stuck. I carefully pull it back out, fix the tape and puckering edges of the gasket. What am I missing? Any pro tips to get this new combustor seated? I wasn't expecting it to be so tight.

Thanks for any recommendations!

Last edited: